2 min read

5 Ways to Improve the Efficiency of Maintenance and Modifications Through Digitization

Matthew Bell : Oct 8, 2020 10:39:34 AM

One of the key challenges towards improving efficiency is the management process used for maintenance and modifications. Historically this type of work has been managed using multiple systems such as excel, which has limitations when managing data in a shared environment. Using multiple systems affects the reporting function, making it impossible to track data efficiently and accurately across the organization. Experience has shown that aging facilities require constant maintenance, and adopting new technology will improve productivity and reduce costs.

Enhance engineering and streamline your scheduling and work execution

Traditionally work is controlled using silos of information across various vendors, systems, and disciplines, with single-point input to expensive planning applications that lack flexibility and require specialist resources to manage. Add to this the mobilization of Dimension control Surveyors to verify engineering solutions, and you begin to see the logistics and cost involved. Data gathering technology has moved on and is far more visible to the extended organization, using photographic quality representation online, reducing the interface cost, while providing total visibility as well as reusable data for future projects.

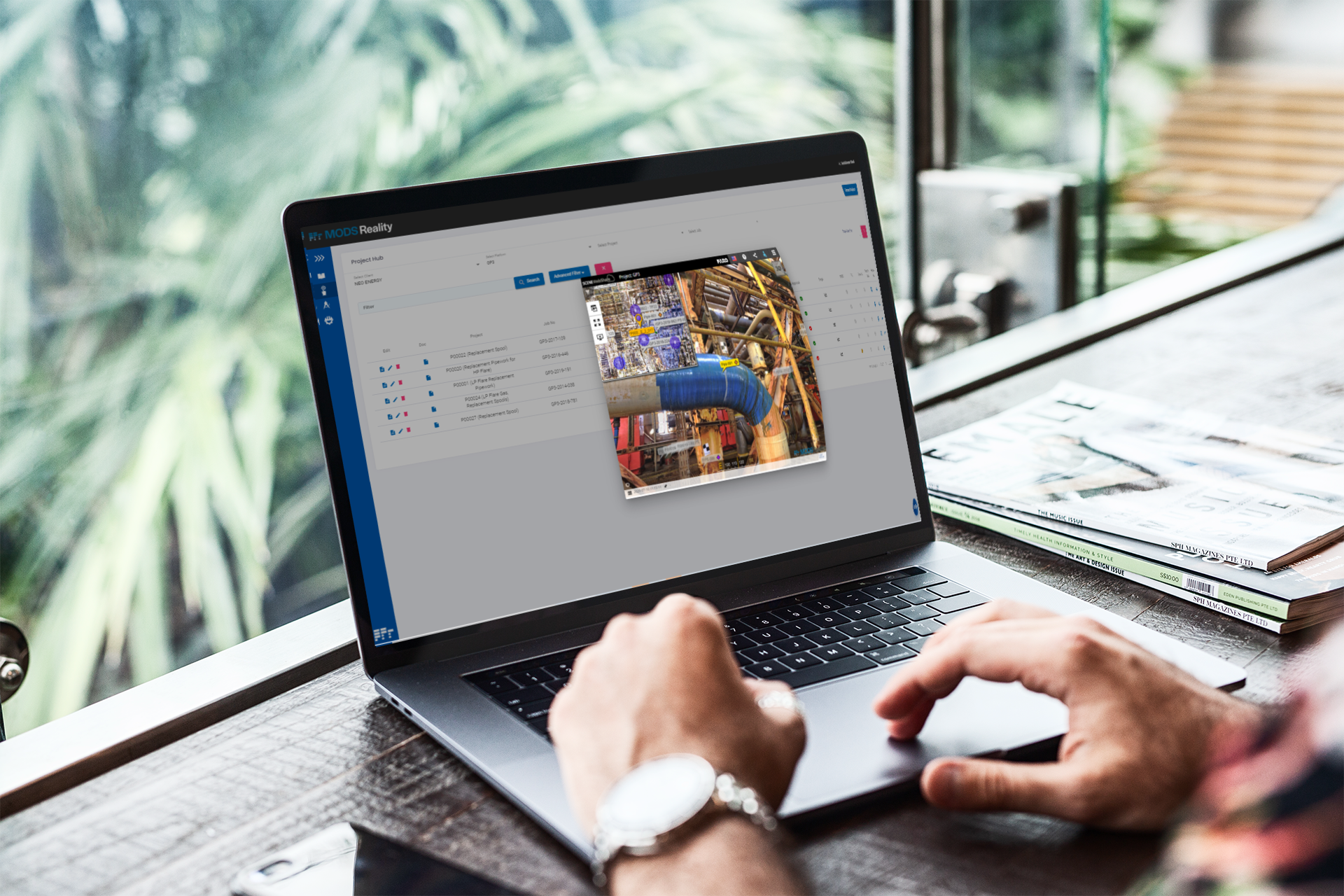

MODS bespoke software “Reality” provides a seamless link between the scanned data directly to digital processes that manage and schedule engineering, procurement, construction, and quality control activities.

Point cloud data is captured, which produces vast amounts of high tolerance engineering data. The data is managed in a shared environment online which provides the visibility to interact directly with MODS Reality applications. Using mobile technology it delivers time now project status and collaboration between Client & contractor, on and offshore.

5 important steps should be taken to optimize offshore repair processes:

Digitalization

Digitalization provides access to data through multiple devices, using processes that automate repetitive tasks. Reality is an online solution that creates a sharing environment that reduces the administrative burden currently experienced using manual, paper-based solutions. The transition to digitalization will transform existing business models and provide a platform for continuous improvement.

Process automation

MODS Philosophy is to improve efficiency by automating repetitive tasks, which can only be done using digital technology. This is demonstrated throughout the software, from cloning and pre-populating repetitive tasks to live reporting in the field to deliver time now updated dashboards and reports.

Collaboration

A system that allows project information to be shared across multiple organizations via a data-centric source providing the ability to visualize, search, analyze and manage work from a single source. Collaboration will significantly improve integrity and efficiency.

Integration

Understanding the significant investments made in existing ERP databases such as planning and documentation systems, MODS Reality has been developed to interface and enhance current solutions. The advantage of this is familiarity with the process, which encourages buy-in from the organization.

MODS full suite of software and services can provide a digital solution from data capture and project control through to construction and handover. We provide a fully integrated system in a single source of truth all tracked via mobile technology:

- MODS Laser Scanning - Capture point cloud data

- MODS Reality – Visually plan, schedule & track Projects

- MODS Connect - Digital Work packs, Material Management and Completions

Mobility

Easy to use mobile technology that empowers field operatives to participate in offshore repair processes, and make decisions on the go. This improves productivity in large or geographically distributed offshore facilities. It provides live status accessible via automated reports and dashboards, removing the need to manually update Excel spreadsheets. The value of mobility and how it eliminates the dependency on on-site infrastructure cannot be stressed enough.

Conclusion

An efficient offshore maintenance project control software solution is one that delivers ROI with better control, helps visualize, analyze, and capitalize with accountable data.

If you would like to know more about MODS Reality, please  .

.

Want to know more about digital transformation? Go check out our Digital transformation - everything you need to know.

Construct-Deconstruct: The Digital Decommissioning Approach

When we think of construction, we typically envision either the creation of new assets or the maintenance and/or upgrade of existing assets. However,...

Digital Completions for Decommissioning Project Success

Offshore decommissioning projects present unique logistical challenges and safety complexities. Dismantling large structures and recovering topsides...