Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

2 min read

Lisa De Vellis, PE

:

Sep 22, 2022 1:05:09 PM

Lisa De Vellis, PE

:

Sep 22, 2022 1:05:09 PM

Building Information Management (BIM), or Building Information Modeling as it's often referred, revolves around the collection, organization and use of construction data that would service the building's lifecycle. Influencing facility design, construction and operation, BIM can be thought of as the foundational step towards digital transformation (DX) of an EPC build.

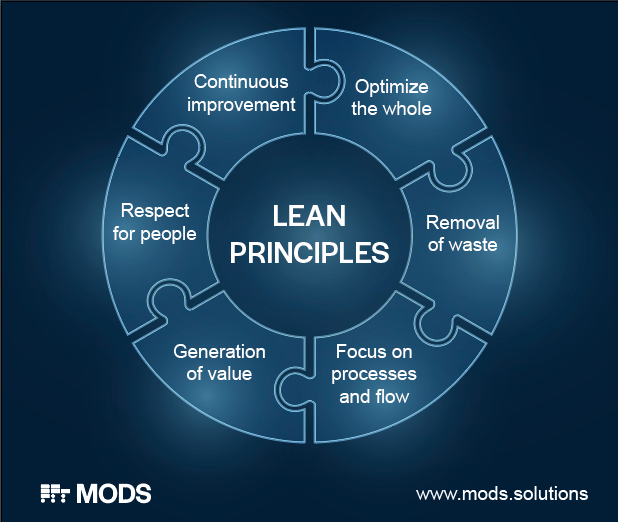

We recently discussed Lean construction principles and how they provide a framework for digital maturity in building and managing a built asset. Where Lean provides the theory, BIM is the process of digitally creating and managing all information related to the design and build of the asset.

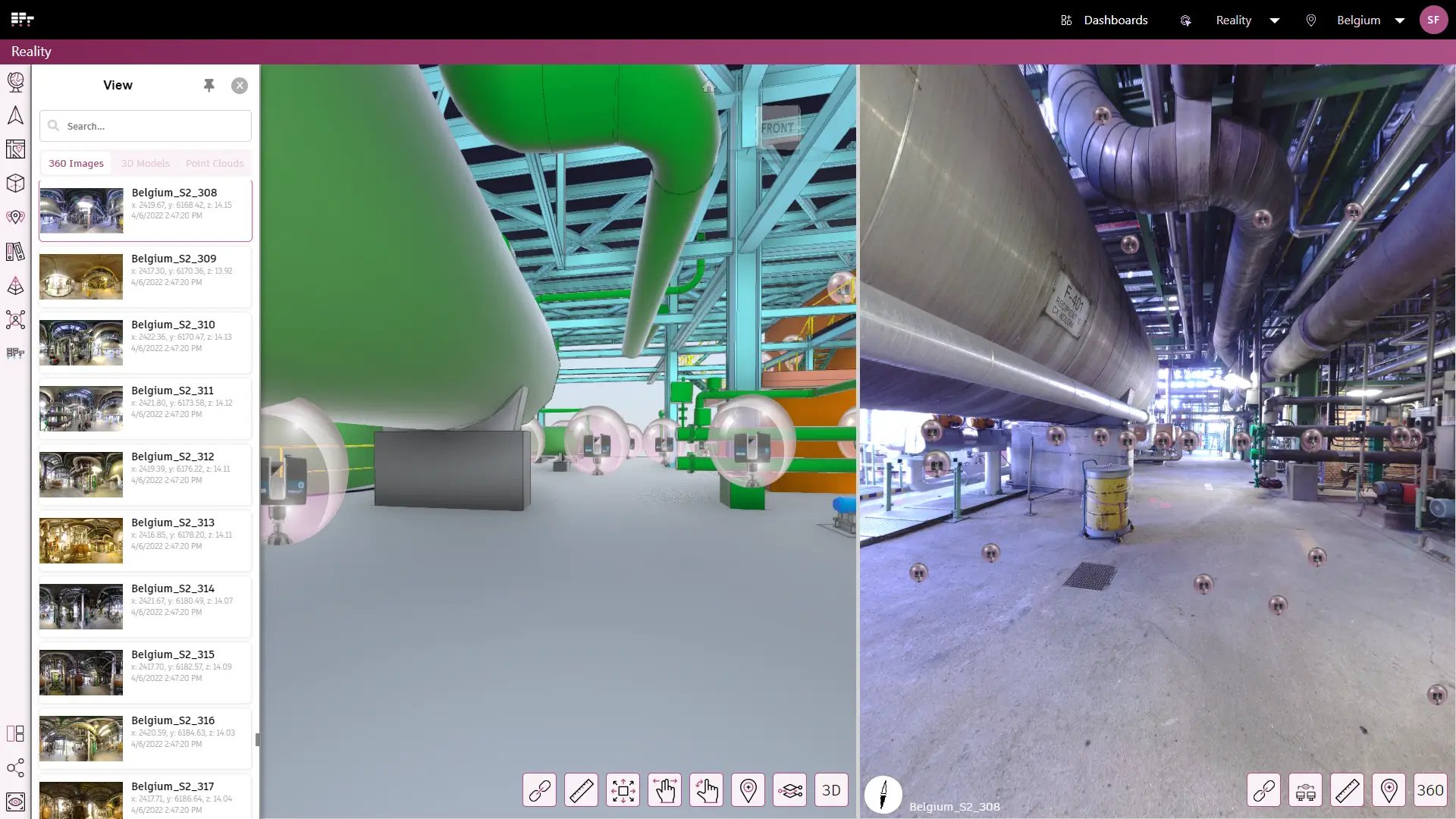

Sounds like a 3D CAD model, right? BIM incorporates everything that a 3D CAD model does: visually representing the infrastructure's geometry, in a digital space. BIM takes that model much further, incorporating construction documentation - that is, data that describe relationships and functionality useful in the construction, operation and maintenance of the built asset.

BIM software in construction incorporates metadata into a 3D visual model of the asset for an improved design-build project experience.

Linking such information to the visual model consolidates multi-disciplinary information into a common dataset that can be viewed or used in a myriad of ways, depending on the chosen platform. The BIM approach eliminates data silos in a way that traditional 3D CAD models can't.

BIM software systems encapsulate tools developed to implement Lean methodology in construction

The BIM suite of tools includes hardware and software used to, as previously mentioned, draft digital as-built drawings in AutoCAD or the like. These digital drawings are comprised of layers, that cross-reference the structural, mechanical, electrical and plumbing infrastructure and avoid layout conflicts. It is strictly geometry-based, speaking to form versus function. These drawings will then be manually updated according to as-built site.

BIM software can be used to facilitate both the construction and facility management processes. These solutions incorporate data drawn from sensor technology, and provide useful information regarding the infrastructure status at commissioning. While BIM builds on CAD models by incorporating metadata that yields insights as to relationships and function, these models still exist as a static picture representing a single point in time.

BIM systems lack the ability to provide continuous real-time status information.

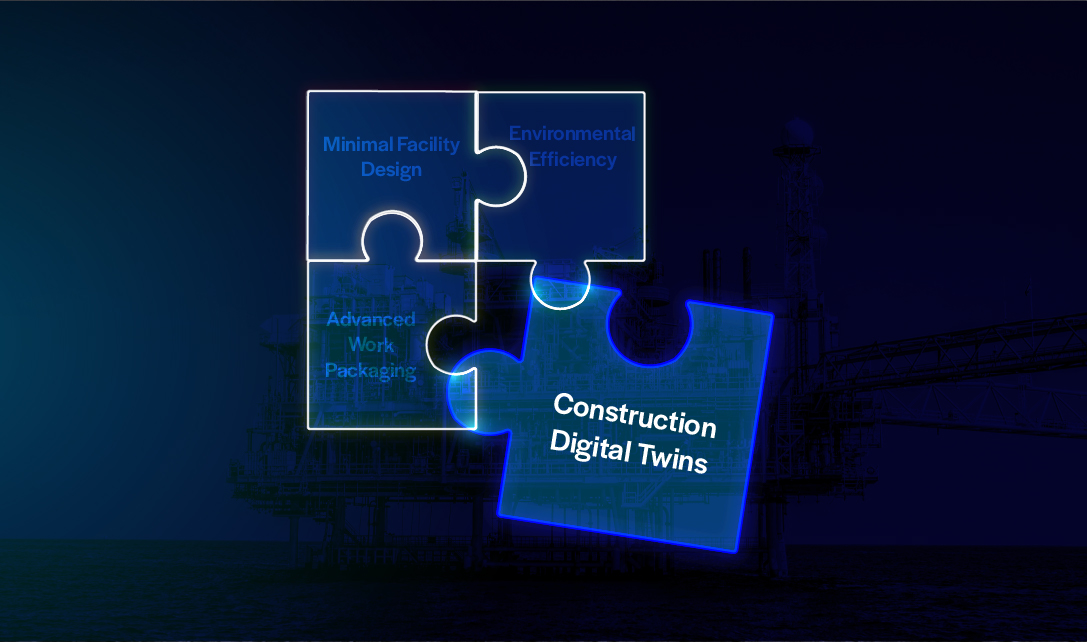

This is where the construction digital twin (DTC) comes into play. BIM is regarded as the underpinning technology of the DTC.

As mentioned, an as-built BIM model effectively freezeframes the completed construction picture for handover to the owner-operator. The BIM model, while unifying multi-disciplinary infrastructure data, is a static picture that excludes any real-time or process information. BIM models, thusly, are not the most effective tool for use in the operation, monitoring and maintenance of the built asset.

The DTC, however, offers a dynamic platform that captures the real-time status and needs of the site. According to Sacks et al. in "Construction with digital twin information systems":

"Digital twin construction (DTC) is a new mode for managing production in construction that leverages the data streaming from a variety of site monitoring technologies and artificially intelligent functions to provide accurate status information and to proactively analyze and optimize ongoing design, planning, and production."

They go on to say that DTC ("a data-centric mode of construction management") incorporates the Lean construction paradigm, BIM technology, the Digital Twin Concept, as well as Artificial Intelligence.

Industrial software for EPC projects benefits from the building blocks of Lean construction and BIM systems. When incorporated into digital twin technology, the EPC construction process from design through handover and into operation and maintenance of the built asset is revolutionized.

As the digital twin is a relatively new concept in the context of construction (ie the DTC), researchers postulate a three-step evolution, paraphrased below:

Certainly, the construction sector is in its infancy when it comes to the true definition of a digital twin. But with Lean principles and BIM systems already broadly established, digital twin technology beckons towards a new era of construction execution.

If you are thinking of implementing digital twin technology to your construction project, check out our  solution.

solution.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

This is the final blog in our four-part series addressing the following energy-sector development trends:

Going paperless by replacing hard-copy information with digital data benefits engineering, procurement and construction (EPC) businesses and...

Sustainability. Decarbonization. Environmental, Social and corporate Governance (ESG). These aren’t just buzzwords, but worthy endeavors increasingly...