Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Decommissioning is an essential lifecycle stage for industrial assets known more so for its financial, environmental and safety risks than for its opportunity. In the North Sea alone, at least 2,000 oil and gas wells are slated for decommissioning over the next decade at an average cost of 7.8 million GBP per well.

It’s a massive market opportunity. But decommissioning is fraught with risks and the potential for bad PR if not carried out to a tee. Digital decommissioning is poised to mitigate environmental as well as occupational health and safety risks associated with complex decommissioning processes, cutting costs, maximizing ROIs and proactively turning a messy public-facing process into a positive one.

When an industrial installation comes to the end of its productive life, or is shut down for economic, political or social reasons (or for some other unforeseen issue), the site, including all relevant infrastructure, must be restored to its previous status in a process called decommissioning.

Decommissioning is more than simply an end-of-asset phase, it is complex and challenging deconstruction process that typically includes shutting down operations and securing the asset, as well as removing and/or repurposing the structure.

Particularly in the offshore oil and gas industry, decommissioning can be hotly contested owing to its environmental and political sensitivities. Mitigating environmental risks during decommissioning is a non-negotiable. Waste disposal and recycling, notably, pose logistical materials challenges that, in the absence of cloud-based management systems, can compromise both the expediency and optics of a decommissioning process.

The next decade will witness a 20 billion GBP expenditure on the decommissioning of aged oil and gas offshore assets throughout the UKCS. Onshore expenses in the decommissioning of offshore assets are minimal, with land-based activities contributing to a mere 2-3 percent of overall decommissioning costs.

It’s clear that the overwhelming majority of decommissioning costs will occur offshore, which is where logistics are far more difficult to manage: crew swaps, getting materials and equipment to and from the site, time delays when working with paper-based work packages and materials management. Responding proactively and flexibly offshore or in otherwise inaccessible locations is severely restricted, especially in the absence of digital systems.

Traditional work packs, notably, retard offshore efficiency through the required physical back-and-forth transport. Eliminating this time lag with digital work packs frees up time and other resources to dedicate to quality assured, safe and compliant decommissioning works.

Data visibility is such a notorious challenge in offshore decommissioning that a Decommissioning Data Visibility Project was launched to tackle the “lack of certainty and transparency around the timing of projects [which] has been a persistent source of frustration for many service companies.”

Decommissioning, as with other lifecycle phases of industrial assets, are traditionally managed through hard-copy work packs and other paper-based systems. When assets are offshore or otherwise not readily accessible, as is the case with the 2,000-plus North Sea oil wells waiting for decommissioning, work pack transit time is wasteful and delays progress of already controversial projects.

The North Sea Transition Authority (NSTA) is the regulatory body overseeing the UKCS energy transition. The body champions the UK government's commitment to reach net zero emissions by 2050, and also aims to create a global competitive advantage for the UK in the decommissioning of the North Sea’s oil and gas assets.

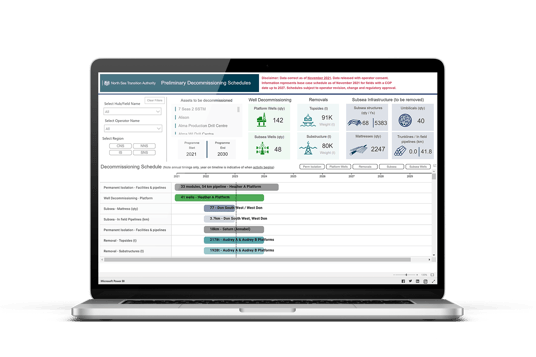

In an effort towards transparent North Sea decommissioning works, the NSTA touts a nifty database of decommissioning schedules.

The NSTA believe that transparency of offshore asset and project data is crucial to achieving both climate and economic targets, and they would no doubt support the use of technological solutions in the form of things such as digital work packs and digital materials management, for example, to facilitate communications and record keeping in the decommissioning process.

The push for data transparency in decommissioning supports the NSTA’s Decommissioning strategy “to help foster a competitive and sustainable decommissioning market.” This is to be accomplished, in part, through a 35 percent reduction in the UKCS decommissioning cost estimate.

Decommissioning complex infrastructure that is integrated into sensitive ecosystems demands sophisticated techniques and comprehensive oversight. Digital tools used to manage decommissioning workflows revolutionize information management. They address the data visibility issue by making archival and real-time asset and project information available to stakeholders anytime and anywhere. Improved data visibility directly translates to ease of compliance, reporting, relationships and even optics surrounding the process.

When we talk about constructing, upgrading and maintaining, it’s about putting things together. But decommissioning, a deconstruction process, is often more nuanced, sensitive and complicated. With a singular digital system housing infrastructure and project data, decommissioning holds the potential to go from a resource drain to a value-added activity, supporting the reuse and circular economy. Valuable infrastructure with the potential for repurposing either as part of the energy transition or transforming into an ecological asset of sorts is supported through easy access and sharing of accurate information.

If you're interested in how digital solutions can help with your decommissioning projects, check out our  .

.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Offshore decommissioning projects present unique logistical challenges and safety complexities. Dismantling large structures and recovering topsides...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

When we think of construction, we typically envision either the creation of new assets or the maintenance and/or upgrade of existing assets. However,...