Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

4 min read

Lisa De Vellis, PE

:

Nov 20, 2023 7:30:00 AM

Lisa De Vellis, PE

:

Nov 20, 2023 7:30:00 AM

When we think of construction, we typically envision either the creation of new assets or the maintenance and/or upgrade of existing assets. However, in the realm of offshore decommissioning, a different kind of construction is at play – the deconstruction of complex structures and systems. While these two processes – construction and deconstruction – may appear worlds apart, the workflows and processes are the same.

Thus, tools beneficial to construction are equally of benefit to decommissioning. Both construction and deconstruction stand to benefit immensely in terms of ROI from the digitalization of foundational workflows: work packs, materials and completions.

In this blog, we explore the concept of decommissioning as a construction process and discuss how digital solutions can transform the approach, execution and delivery of these challenging projects.

Decommissioning is a process that involves the systematic dismantling, removal and recycling, reuse or disposal of offshore topside structures that have reached the end of their operational life. While the end goal is the opposite of construction – reducing and removing structures – the workflows involved are analogous to those of construction.

Digital solutions are transforming the construction industry, streamlining workflows, enhancing safety, improving efficiency and encouraging sustainability. The same principles apply to decommissioning. Here are some key workflows where digitalization is poised for significant impact:

Digitalizing all of the above decommissioning workflows positively impacts scheduling, budget and safety throughout the project’s lifecycle. Safety, in particular, is a top priority in both construction and decommissioning. Digital solutions enhance safety via transparent recordkeeping, accessibility of real-time and archival information and by enforcing protocols. Digital tools reinforce a Safety First project approach.

Digitalizing offshore decommissioning workflows brings a range of benefits:

The concept of decommissioning as a construction process, though seemingly unconventional, holds substantial merit. By recognizing the commonalities in workflows between construction and decommissioning, we can apply the lessons and benefits of digitalization to both domains.

Digital solutions are transforming the decommissioning process by optimizing work pack, materials and completions workflows, while enhancing project safety, compliance and sustainability. As the industry continues to evolve and embrace digital technologies, decommissioning projects are poised to become more efficient, cost-effective and environmentally responsible; and the market is ripe for the picking. This shift not only streamlines the deconstruction process but also ensures a sustainable and efficient future for offshore decommissioning.

Want to learn more?

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Offshore decommissioning projects present unique logistical challenges and safety complexities. Dismantling large structures and recovering topsides...

Decommissioning is an essential lifecycle stage for industrial assets known more so for its financial, environmental and safety risks than for its...

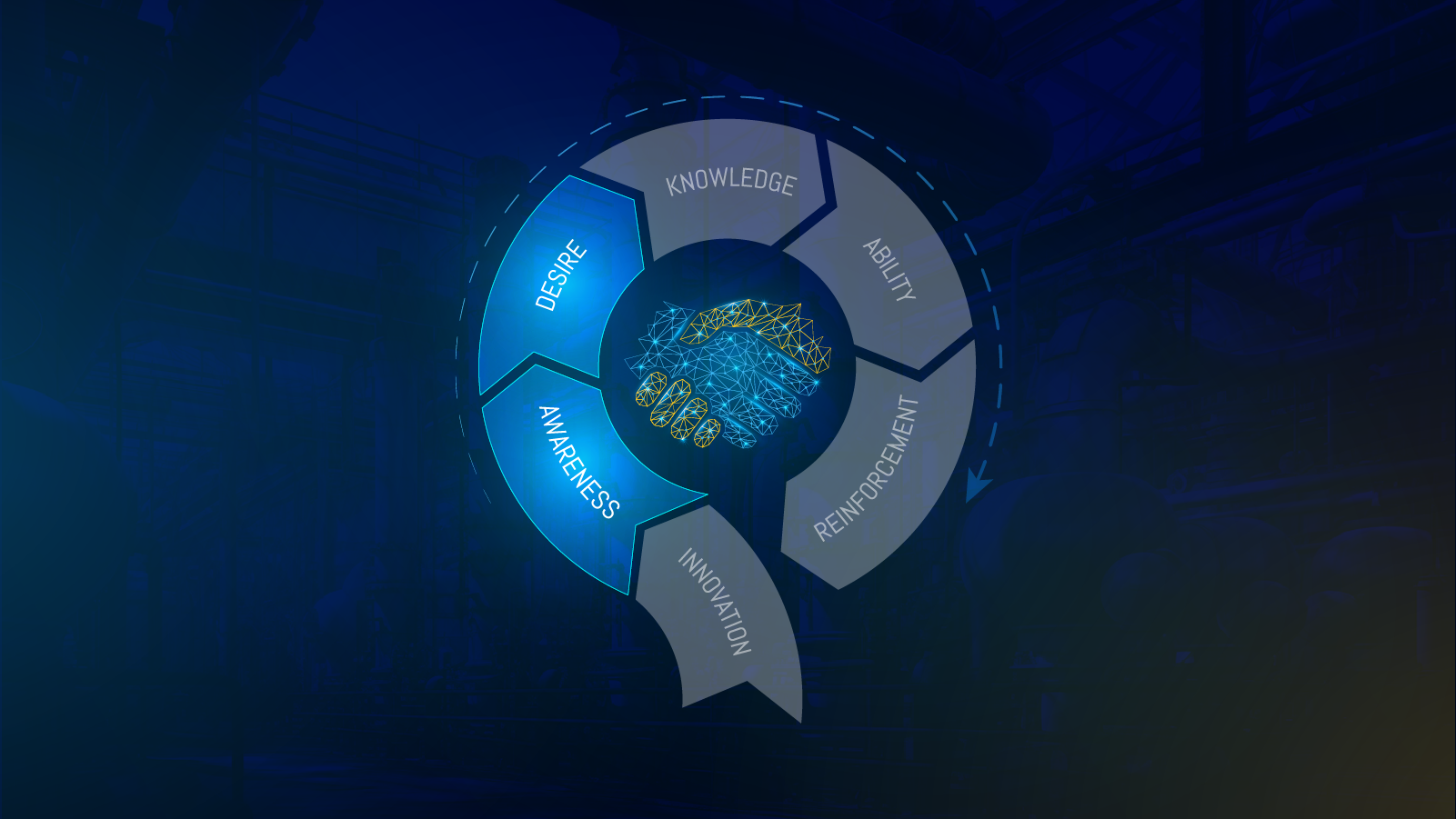

Change management frameworks can help identify barriers to the successful adoption of new technological solutions. The ADKAR model of change...