Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

3 min read

Lisa De Vellis, PE

:

Oct 28, 2022 12:45:37 PM

Lisa De Vellis, PE

:

Oct 28, 2022 12:45:37 PM

The two-day Advanced Work Packaging (AWP) North America conference in Houston on 17-18 October revolved around daily themes of Improving Project Delivery and Leveraging Technology to Improve Project Outcomes.

The Construction Industry Institute (CII) gives the following best-practice definition for AWP:

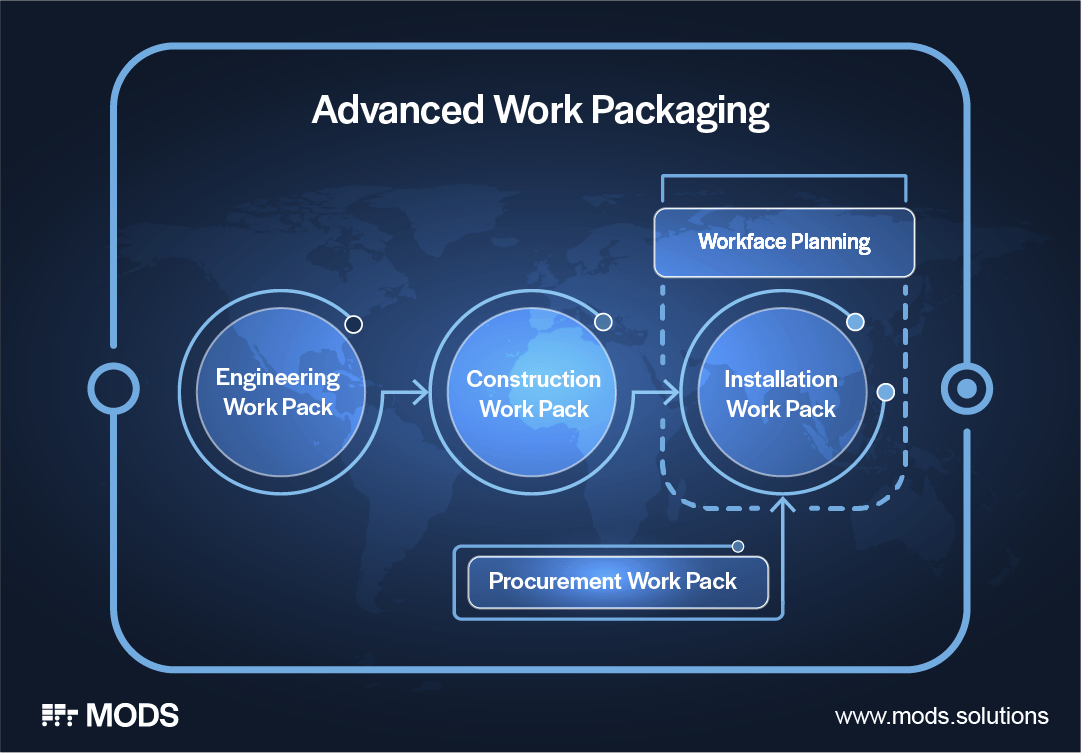

“The overall process flow of all the detailed work packages (construction, engineering, and installation work packages). AWP is a planned, executable process that encompasses the work on an EPC project, beginning with initial planning and continuing through detailed design and construction execution. AWP provides the framework for productive and progressive construction, and presumes the existence of a construction execution plan.”

Effectively, Advanced Work Packaging, or AWP, harnesses the data of capital construction projects from engineering design including procurement deliverables, through construction and into workface planning and installation. The amalgamation of design, construction and installation data can be used to populate 3D asset models to reduce project risk, streamline execution and improve project outcomes.

Day 1 of the North American AWP Conference in Houston carried the theme of Improving Project Delivery with AWP. The first day focused on discussing what AWP is, with capital project leaders addressing questions such as: What’s the optimal focus to improve project delivery? How to implement AWP and is your company ready? What are project risks and how does AWP address these?

During the sessions on this day, speakers discussed their AWP successes to date alongside the challenges they’ve faced. Attendees collaborated on identifying best practices and how best to leverage AWP.

The CII’s Josh Fish discussed recent research on AWP that has revolved around the Engineering and Construction phases. The CII has also engaged in Commissioning-phase research over the past 6 years. Collectively, these research initiatives revealed the opportunity to integrate AWP approaches into both the Commissioning and Startup phases of capital projects, expanding the scope of AWP.

Another breakout session on Day 1 led by Lloyd Rankin from Group ASI recommended best practices for when a project is launched with AWP. Participants discussed their experience and the organizational ability to implement AWP on projects. Ensuring all project stakeholders have compatible understandings of how the project should be planned and executed is of paramount importance.

With AWP in place, both internal and external risks reduce.

Internal project risks include:

External project risks include:

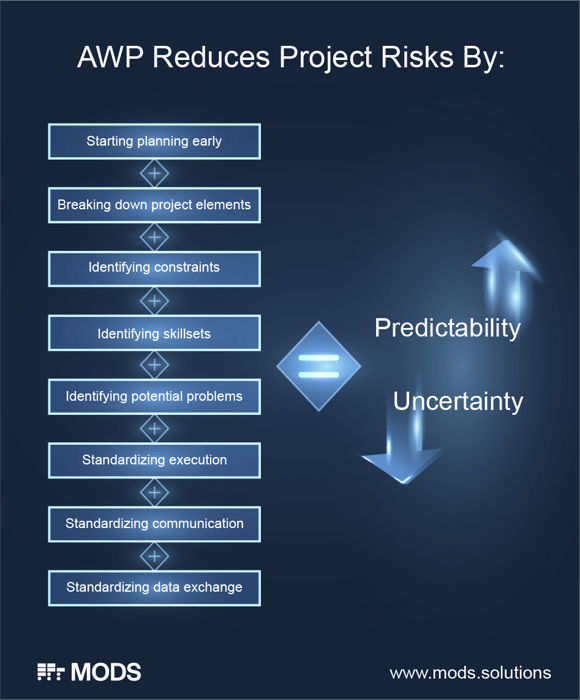

How does AWP help address these project risks? With the holistic AWP approach, planning starts early and breaks-down project elements. AWP identifies constraints and skillsets, therefore calling out potential problems in advance and allowing for informed decision making. AWP standardizes processes, including project execution, communication and data exchange.

Through reducing external and internal risks as well as standardizing processes through the collation of project data, AWP reduced uncertainty and increases predictability, thereby improving project outcomes.

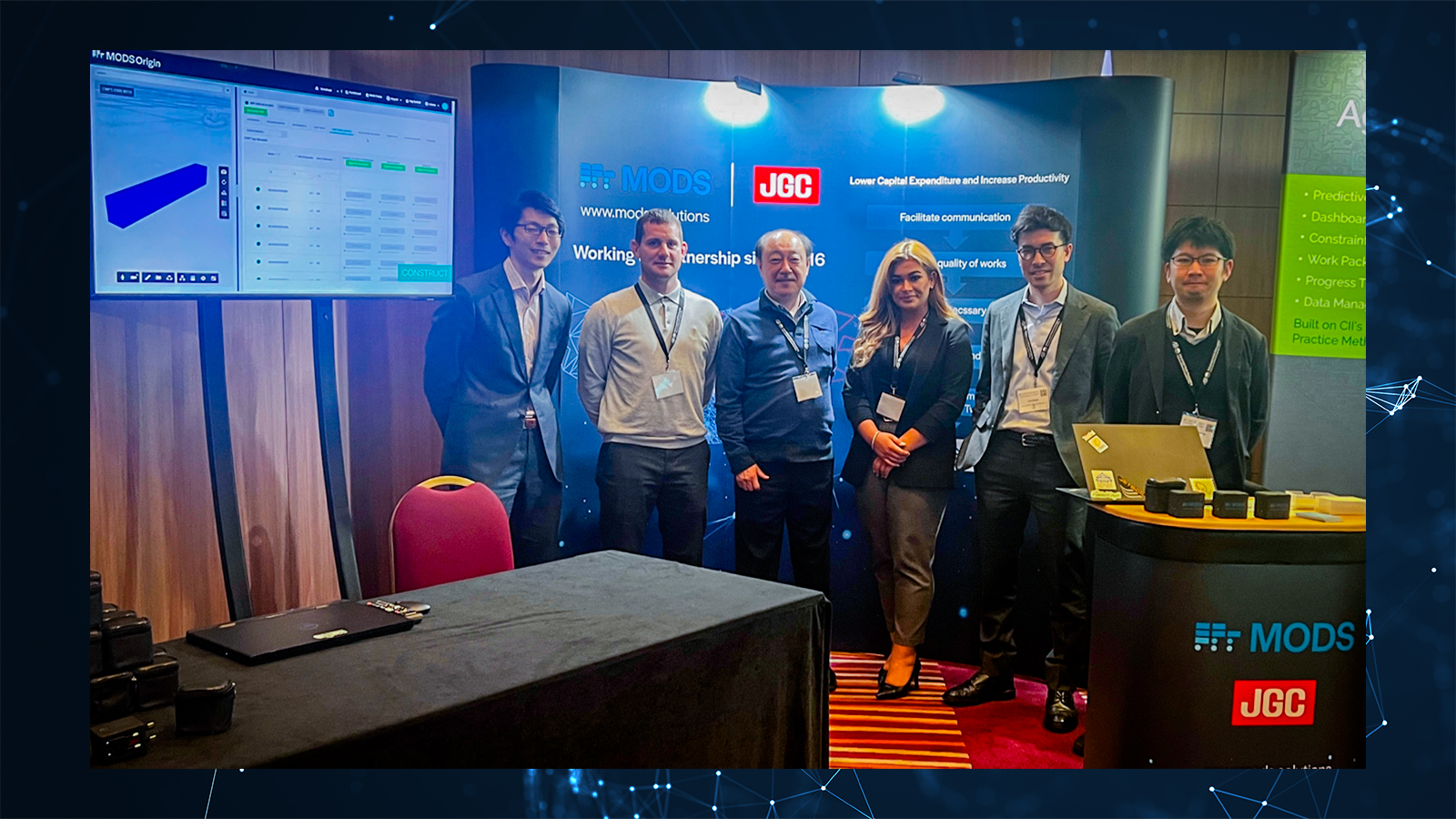

Day 1 of the conference was capped off with the 2022 AWP Awards ceremony wherein we proudly watched our partners JGC receive their Large Project Award through use of MODS Origin on part of a USD 40 billion Total Installed Cost (TIC) project in Quin dao, China. This project was a resounding success in how AWP impacts project delivery. For more on how JGC has successfully implemented AWP in their capital projects, read our case study.

Day 1 of the conference was capped off with the 2022 AWP Awards ceremony wherein we proudly watched our partners JGC receive their Large Project Award through use of MODS Origin on part of a USD 40 billion Total Installed Cost (TIC) project in Quin dao, China. This project was a resounding success in how AWP impacts project delivery. For more on how JGC has successfully implemented AWP in their capital projects, read our case study.

The Day 2 Conference theme was Leveraging Technology to Improve Project Outcomes, which explored which technological options are available for AWP, how to harness the power of these technologies and which ones your company ought to pursue.

Discussions included which strategies are worth pursuing and how to close gaps in construction execution. Statistics revealed that other industries see up to three times more productivity with the implementation of technology – a clear nudge for construction execution of industrial capital projects to get on board.

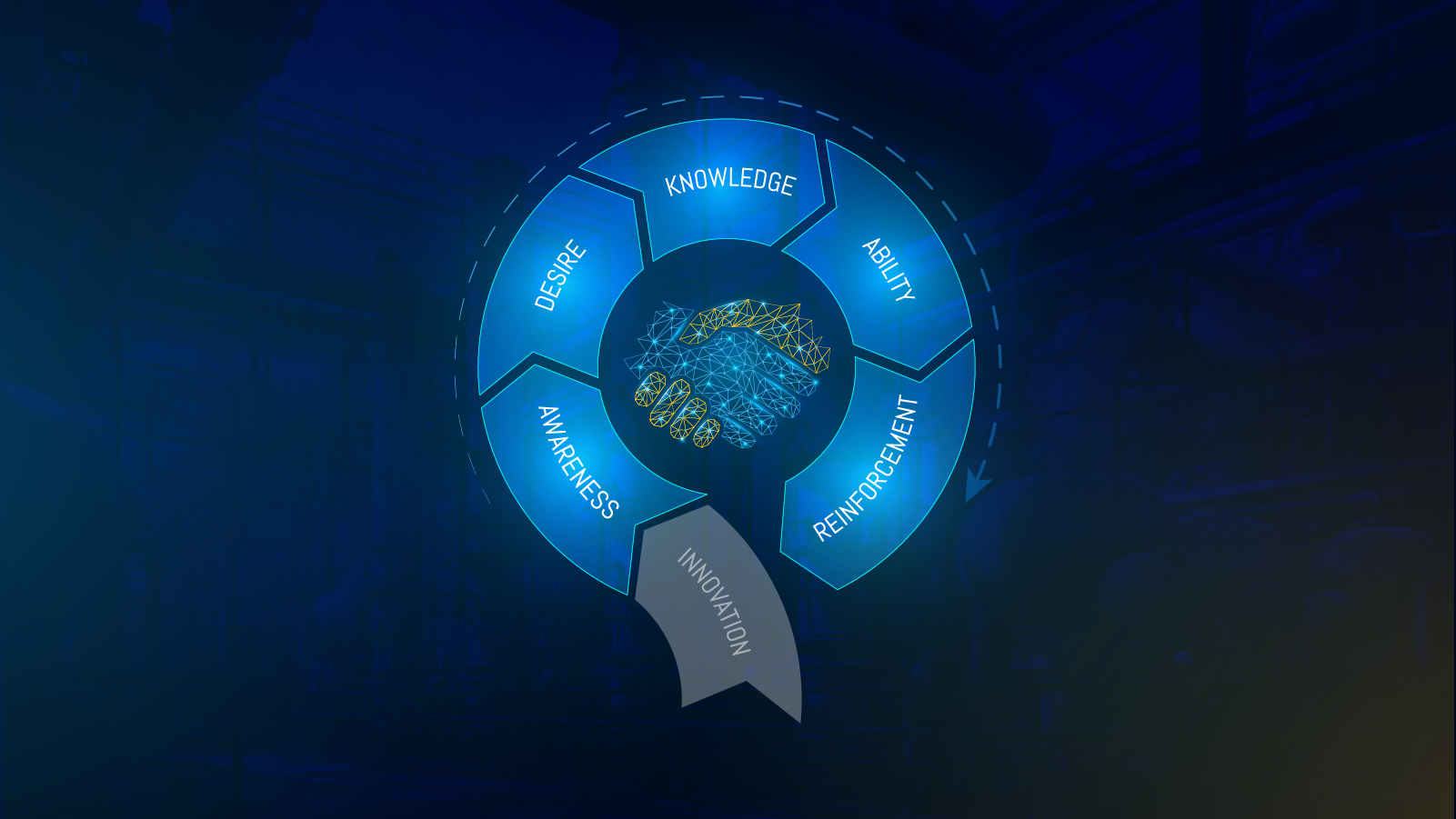

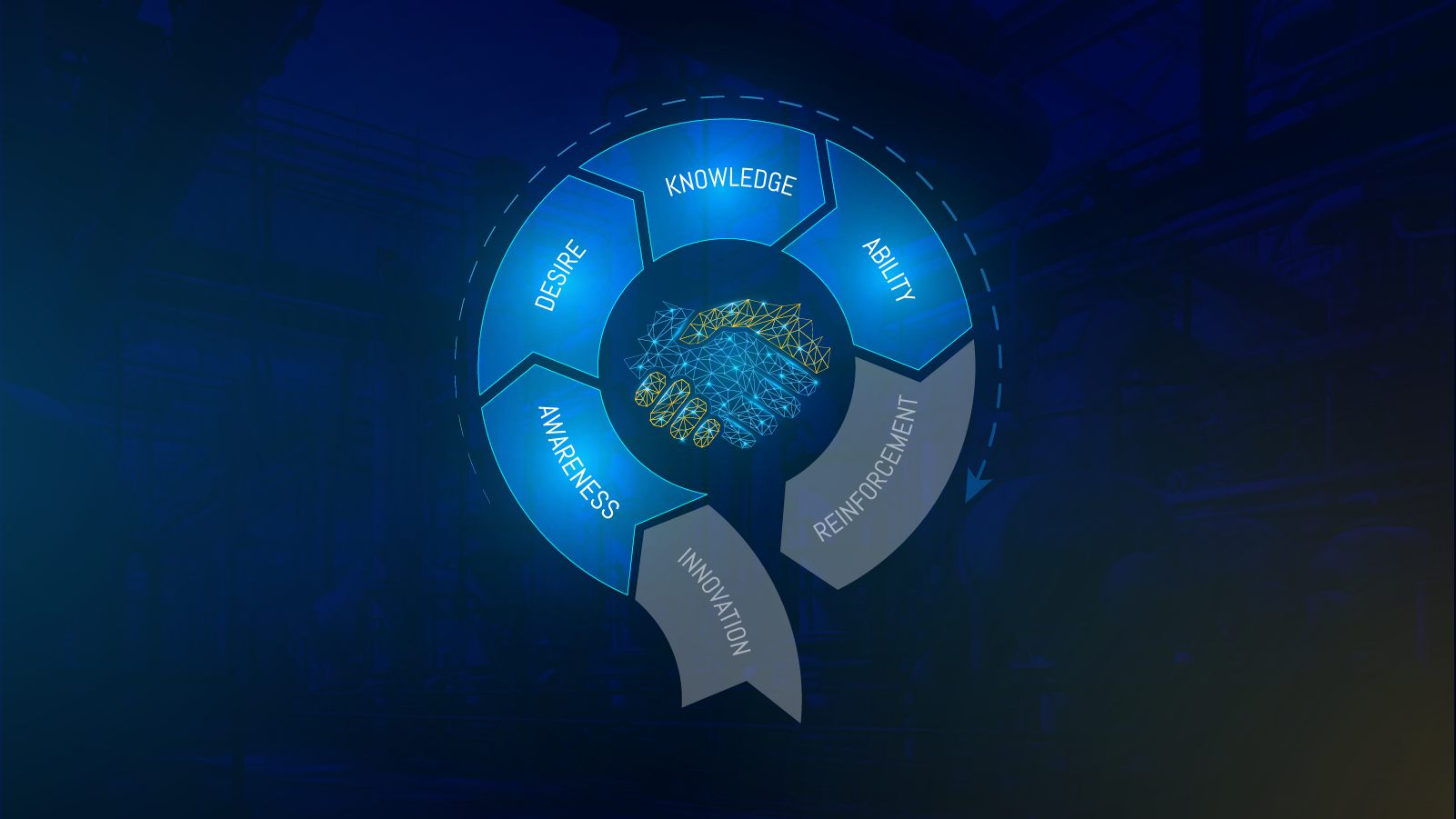

Yuto Hori, Product Manager with JGC, led a breakout session titled: The Future of Construction and Engineering Management in AWP. Yuto presented the deep world of engineering management through the lens of developing an AWP management system. He shared lessons learned through JGC’s digital evolution and other research avenues, and discussed the AWP risk-reduction strategy and how JGC build their projects with AWP to radically improve performance. Yuto explained that improving project delivery requires technology, but highlighted that technology is more than just software.

Another breakout session covered AWP data requirements, why they are critical to project success and how these can be included in contracts. Maximizing cost effectiveness of projects was discussed, though there is limited knowledge regarding how to successfully implement modularization.

Another breakout session covered AWP data requirements, why they are critical to project success and how these can be included in contracts. Maximizing cost effectiveness of projects was discussed, though there is limited knowledge regarding how to successfully implement modularization.

The CII group serve to fill this gap, helping companies understand how modularization, including AWP and other tools, can be successfully implemented on a project basis. The CII shared a current research project that they are working on to that end. Their RT-396 research project involves developing a tool to help companies with a business case for modularization.

The North America AWP Conference drove home the power of AWP. Its potential is expansive and, largely, untapped in the construction of industrial capital projects. AWP leverages technology to radically improve project delivery. Selecting a digital partner and capitalizing on resources such as those from Group ASI and the CII can help you initiate and navigate your digital transformation journey with AWP or other project delivery tools.

Check out MODS AWP solution,

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Advanced Work Packaging (AWP) as a capital project delivery solution is revolutionizing construction productivity. Striving towards cost reduction of...

“Even the most advanced technology can’t achieve anything by itself. Value emerges as a combination of the tool and the people who operate it....

To realize increased efficiencies in construction execution, the ability to adapt to change by onboarding new technologies is paramount....