Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Here is a checklist of items to get Advanced Work Packaging (AWP) implementation off on the right footing. It is not a complete list but covers some tips and tricks that can be implemented from engineering, procurement and information management standpoints to get your AWP project off to the right start.

Implementing Advanced Work Packaging (AWP) methodology supported by robust software tools is pivotal for competitive, successful project delivery. The engineering, procurement and information management tips and tricks outlined in this checklist are intended to help organizations navigate the complexities of AWP implementation with greater confidence and efficiency from the get-go.

Embracing AWP not only enhances project delivery timelines but also fosters collaboration, mitigates risks and ensures alignment across project teams. The integration of intelligent industrial software solutions, such as MODS Connect, as unified AWP platforms further empowers organizations to orchestrate seamless coordination, optimize resource allocation and drive data-driven decision-making throughout the project lifecycle.

As industries evolve and project complexities grow, adopting AWP methodology becomes imperative for staying competitive and achieving operational excellence. By leveraging these tips and tricks, MODS hope you will embark on your AWP journey equipped with the knowledge and tools necessary to drive success in today's dynamic industrial landscape.

AWP isn't just a methodology—it's a strategic imperative that enables organizations to maximize productivity, minimize costs and deliver superior outcomes. By embracing innovation and harnessing the power of technology, companies can unlock new levels of efficiency and effectiveness in their project execution.

Learn more lessons on our free webinar:

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

MODS develop award-winning Advanced Work Packaging (AWP) tools and work alongside global partners to deploy AWP on everything from mega-projects to

Advanced Work Packaging (AWP) has fast become best practice for industrial projects. Owner-operators increasingly stipulate to EPC contractors that...

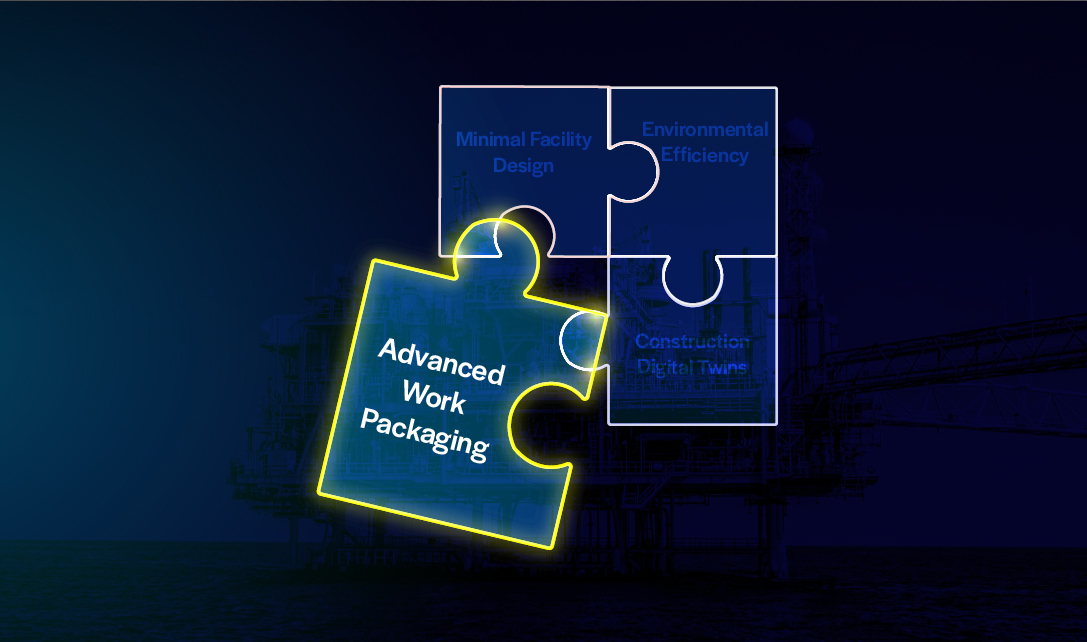

This blog is the second in a four-part series looking at the following future trends in energy sector facilities: