Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

What are work packs? Well, it depends on whom you ask. Work packs, or work packages, is a somewhat generic term used across the design-build-operate-maintain-decommission lifecycle of an asset (for our purposes here, specifically for an industrial asset).

Work packs, depending on the type and project phase, define everything from engineering design (ie Engineering Work Pack, or EWP), to construction methodology, (ie Construction Work Pack, or CWP) and construction execution (ie Installation Work Pack, or IWP).

Certainly, the IWPs flow from the contracted CWPs, which are, in turn, predicated on the EWPs.

Depending on the pre-determined bidding process as well as the EPC contractor’s level of sophistication, the overarching work-package concept is somewhat of a sliding scale in terms of what these deliverables actually look like.

But, assuming the bid has been won, it is the IWP that we at MODS, as an SaaS provider, commonly refer to as a work pack, or work package, because these are the dossiers used during construction execution, commissioning and startup.

A project’s Work Packs collectively detail the set of instructions for how to carry out the construction activities or maintenance routine for the particular scope of work in question. One Work Pack bundle, which in paper form can be hundreds of pages long, subdivides industrial construction projects into more manageable components.

A single Work Pack consolidates information pertaining to everything from engineering design, materials (fabrication and inventory), equipment, installation specifications, worker requirements, health and safety, scheduling and estimated time for the specified scope (which, again, is effectively a bite-size piece of the project at large). Even one Work Pack is a substantial deliverable in and of itself.

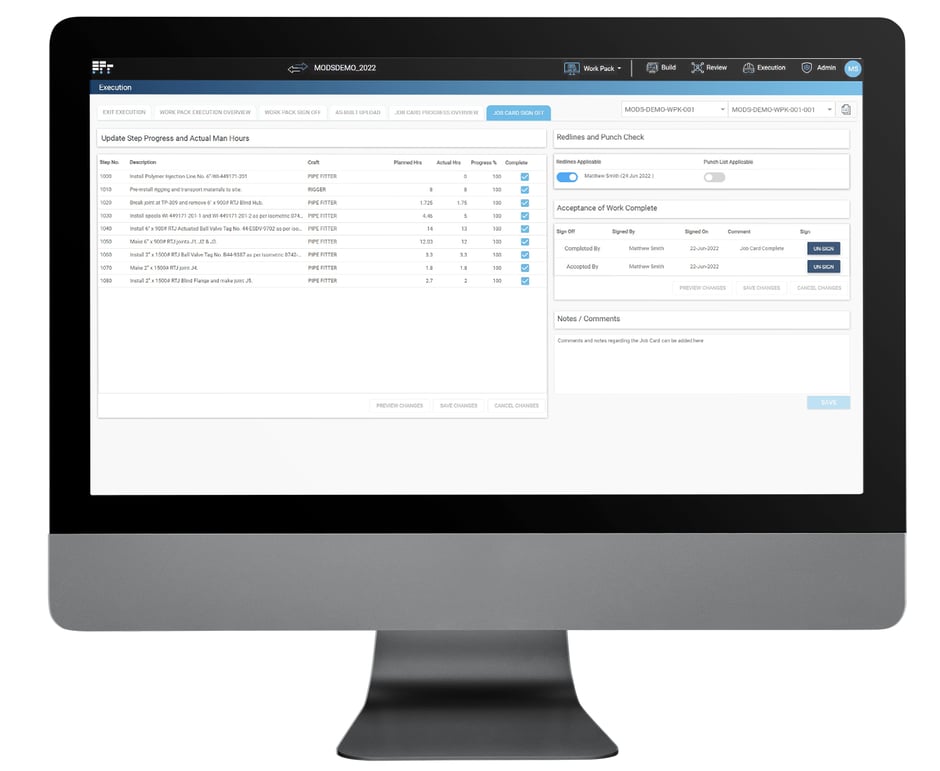

A Work Pack is subdivided into Job Cards, which are the discipline-specific instructions for a scope of work covered within the larger work package. So, whether for mechanical, electrical, plumbing or instrumentation, each delivery team receives a tailored directive in the form of Job Cards.

A Job Card details the trades and tasks in question. The design specifications (ie drawings), safety considerations, potential conflicts and inspection requirements. Additional elements such as milestones, worker hours, bills of materials, risk assessments, as well as outlining roles and responsibilities are also included in job cards.

Each Job Card has a uniquely identifying number or code with a brief discipline-specific description, such as pipework hookup. Project details are referenced as is the revision number of the Job Card, dates and priority are indicated, and it is linked to a specific Work Order. The area, system and sub-system are all identified, and there’s space for safety quality assurance and approvals. A series of Job Card notes with detailed worker-hour estimates outline the sequential order of tasks – these are the Activities.

Activities (or Steps) are the individual line tasks required to collectively fulfill a job card scope. Activity directives include details required to carryout a task, including both the trade and estimated worker-hours.

Work Packs, Job Cards and Activities are a hierarchical structure that breaks down and organizes industrial construction and maintenance projects into tangible parts.

Traditionally, work packs for industrial construction and maintenance exist as paper documents, often in the hundreds of pages long. Paper-based work packs are laborious and resource-intensive to prepare, to navigate, to carry-out and to reference back for archival purposes.

Work pack software solves the myriad of problems associated with old work pack methodology, such as time-and-cost overruns, compromised safety, loss of information, lack of adequate records, as well as compromised accountability and transparency.

Digital work pack software reduces room for human error with features that include the following:

Traditional work pack lifecycles are long. When dealing with large paper-based work pack folders for offshore or other remote projects, it can take up to to 1-2 weeks for these documents to reach the site. Shipping and closing-out such hard-copy work pack documentation can take a whopping 60-90 days.

The plague of physically transporting paper-based work packs to sites, especially those offshore, can interrupt sequential activities or otherwise delay work. With cloud-based work package software, remote and agile work pack management for the construction and maintenance of industrial assets is possible.

Hard-copy Work Packages require physical transport and physical signatures, all of which eats into time, resources and money. Work Packs are essential documents that guide construction, installation, maintenance and decommissioning works. So it goes that any Work Pack inefficiency poses significant downstream effects in terms of actually getting the job done.

Digital Work Pack solutions have revolutionized the way that EPCs and Operators can manage the construction, upgrades and maintenance of their industrial assets. This is done through cloud-based software superior to on-premise files. Digital cloud-based Work Pack solutions streamline processes, enhance communication, enabling transparency and overall quality of information management, saving oodles of time and money.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Work packages drive forward progress in Engineering, Procurement and Construction (EPC) projects, regardless of whether the Assets are newbuild or...

Work packages, or work packs as they’re more commonly called, are the instruction manuals for works required across the...

We have talked about how digital infrastructure is the keystone to Lean Construction and enabling BIM systems for the modernization and optimization...