Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

2 min read

Lisa De Vellis, PE

:

Oct 7, 2022 1:46:55 PM

Lisa De Vellis, PE

:

Oct 7, 2022 1:46:55 PM

We have talked about how digital infrastructure is the keystone to Lean Construction and enabling BIM systems for the modernization and optimization of the construction, installation, maintenance, operation and decommissioning of industrial assets.

Work packages are a guiding force in project success because they subdivide these massive engineering endeavors into tangible, executable, bite-size pieces. If work packs are erroneous, incomplete or delayed, the downstream amplification of these issues can be ruinous in terms of project outcomes with regard to both time and money.

A solution exists. Digital work pack software embodies the Lean construction ethos, reinforcing the paradigm that time, materials and value matter.

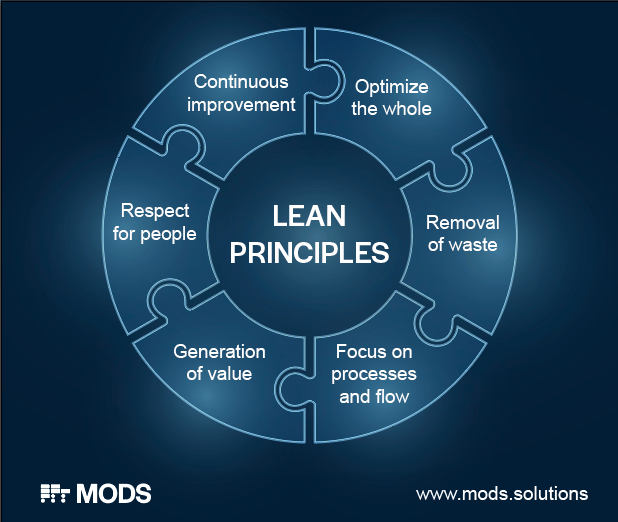

Let’s summarize what Lean construction principles involve. There are six overarching tenants, as follows:

These Lean construction principles reinforce the Lean methodology, which is to optimize the transformation of materials into a built asset, in as time-and-cost efficient manner as possible. Hence, materials, time and value drive Lean construction.

Digital work packages, when replacing traditional hard-copy ones, are a guiding force that enable the smooth evolution of project execution from design through to completion.

When work packs are paper-based and rely heavily on manual processes such as physical signatures and manual data entry into incompatible systems. These work packs of yore are not optimized. Certainly, this is important because then excesses of time and money are wasted.

Time and money may be the ultimate determinates of a project’s outcomes. Certainly, worker hours and resource use (eg materials, equipment) matter. But what contributes to these costly overruns?

When workflows are suboptimal – as is the case with archaic work pack methods – both quality and safety suffer from compromised oversight. Poor quality of work impacts reputation, safety and demands time-consuming rework. Further, industrial settings demand a safety-first mentality. Slow and cumbersome systems and processes muddle information and can compromise worker safety and environmental health.

Communication is key. Navigating sequential activities and complex tasks involving multidisciplinary teams at remote or inaccessible locations is challenging. Digital work packs untangle this bird’s nest, making workflows and communication as linear as possible, optimizing workflows. This way of working reinforces quality and safety, respecting schedules and budget constraints.

The digital approach to work packs follows the Lean construction approach. When flipped around, Lean construction demands digital work packaging solutions to streamline workflows, cut out waste, optimize safety and quality. This saves time, materials and adds project value.

Digital work packs support each of the six guiding Lean construction principles. The benefits of using work pack software versus traditional paper-based systems, all of which reinforce Lean construction ideology, include:

The aforementioned benefits of work pack software solutions in place of old-fashioned methods revolve around waste reduction both in terms of time and material resources.

The Lean construction framework focuses on minimizing waste and, hence, maximizing value. Waste in construction manifests in two forms: materials and time. Work package content details materials (including equipment) and labor (ie time) required to carry out the identified activities. The synergy between digital work packs and Lean construction is obvious.

Digital work packs streamline workflows to deliver value. In other words: work packaging software solutions reduce materials and time wastage, increasing project ROI.

Check out the MODS  solution and get in touch with our WP specialist.

solution and get in touch with our WP specialist.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Efficiency and optimization are the hallmarks of Lean construction. The role of digital infrastructure cannot be overstated as an essential tool in...

When we think of construction, we typically envision either the creation of new assets or the maintenance and/or upgrade of existing assets. However,...

Infrastructure consumes over half of the world’s materials and is the largest contributor to greenhouse gas emissions worldwide. Approaching capital...