Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

4 min read

Lisa De Vellis, PE

:

Oct 16, 2023 8:00:00 AM

Lisa De Vellis, PE

:

Oct 16, 2023 8:00:00 AM

In the construction execution of complex assets such as brownfield projects, embracing digital transformation (DX) is increasingly important. The adoption of new digital tools plays a pivotal role in enhancing construction efficiency, reducing costs, and, ultimately contributing to a sustainable future by streamlining workflows and reducing a project’s carbon footprint.

However, the successful integration of these digital tools into construction and maintenance projects in challenging contexts such as offshore oil and gas requires more than just Awareness and Desire. It hinges on the crucial third step in the ADKAR change management model: Knowledge.

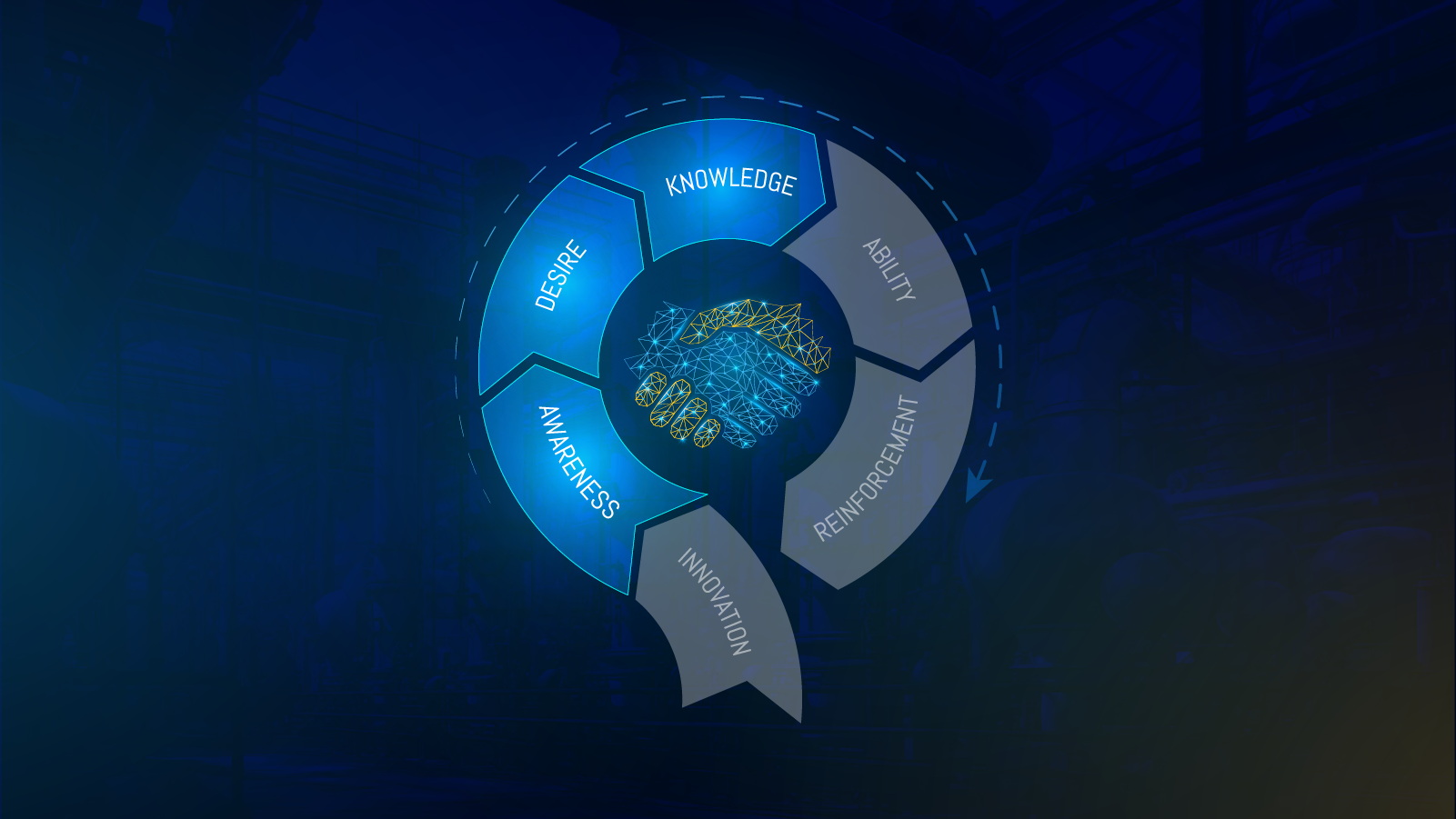

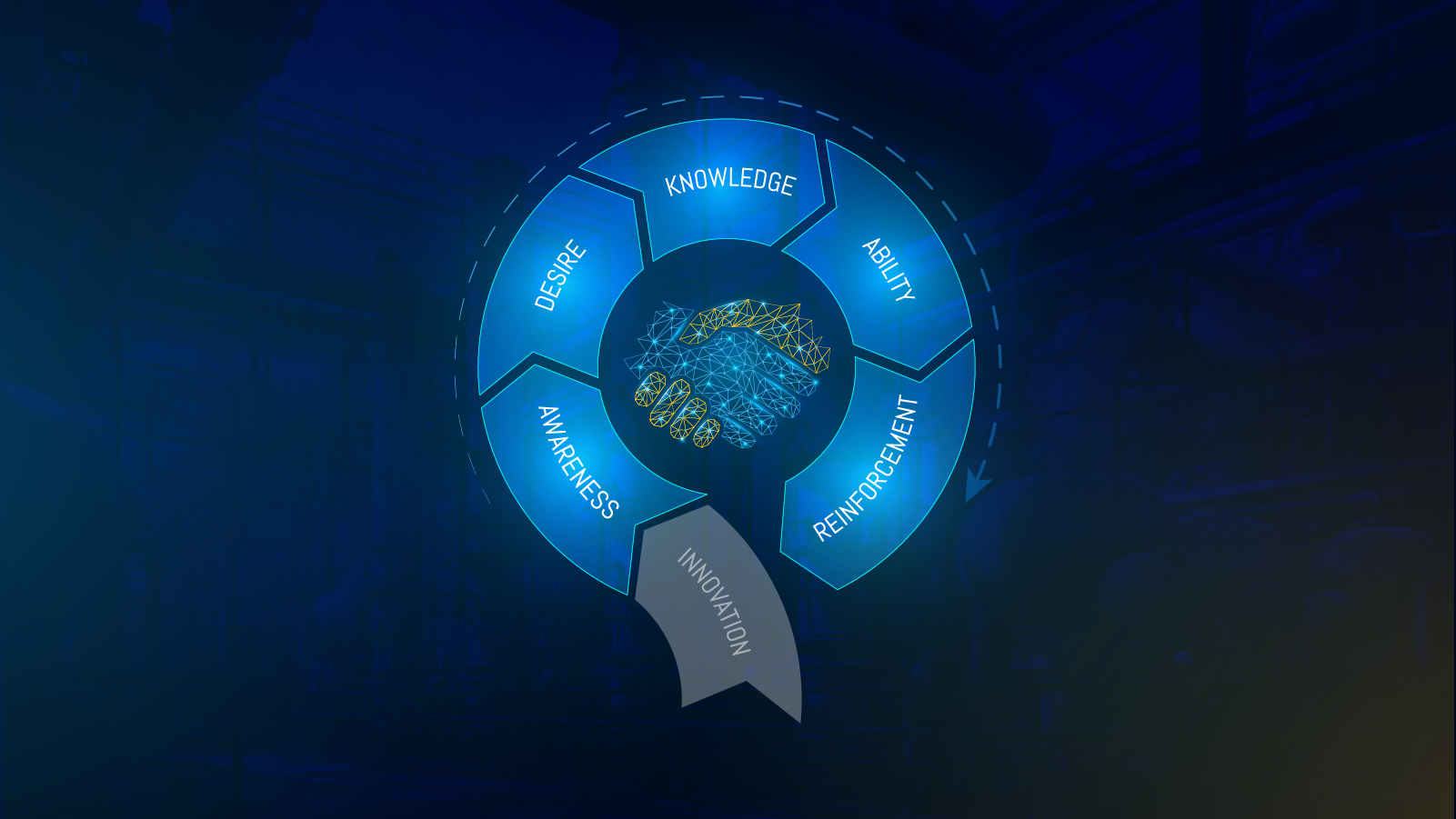

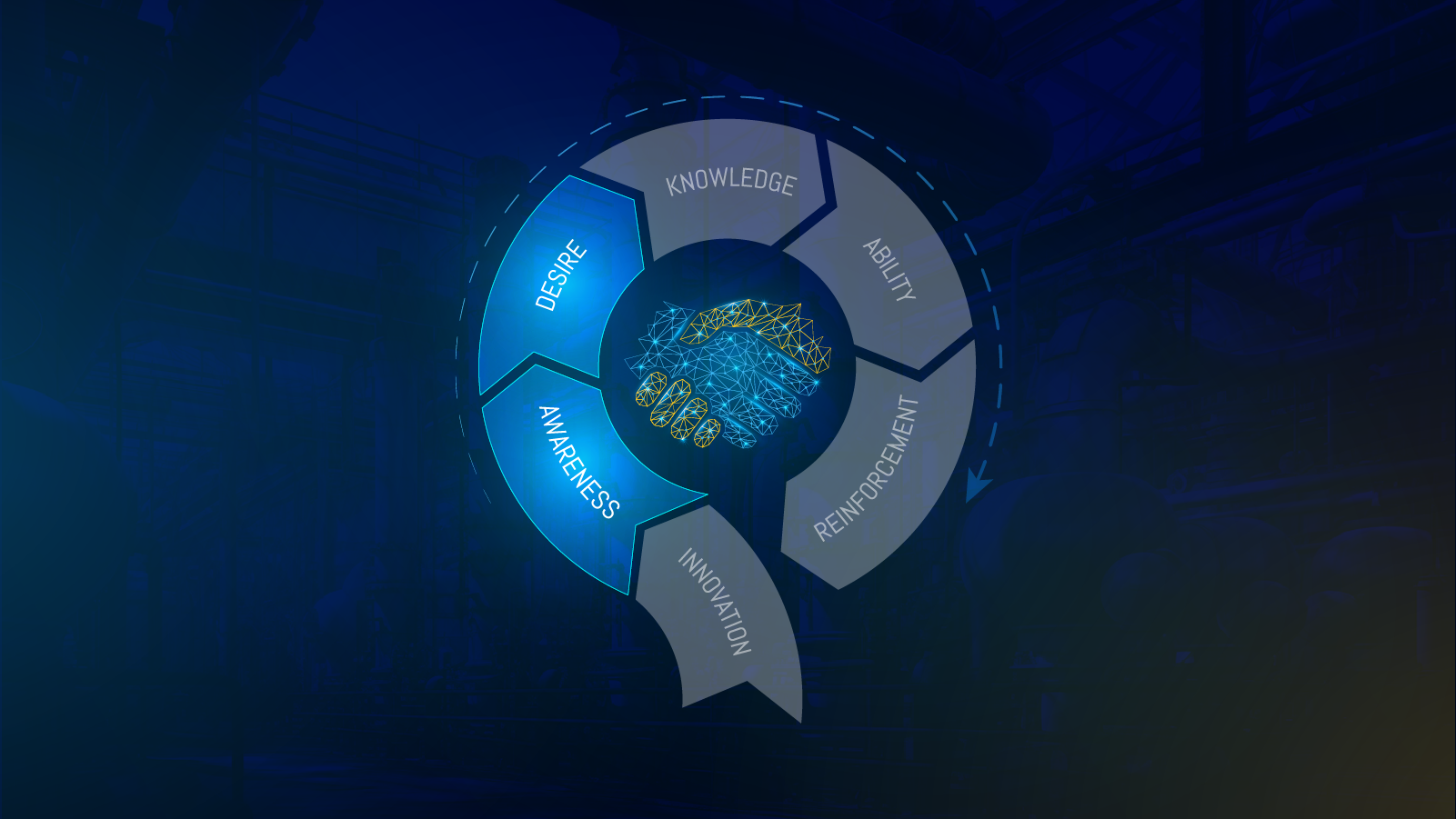

ADKAR offers a user-centric DX framework for lasting cultural transformation, supported by the following 5-steps:

In this blog, we will explore why imparting Knowledge to end-users is essential in the uptake and scalability of new digital tools during a digital transformation journey in brownfield and other challenging construction projects. This blog is part of a series dedicating attention to each of the 5 ADKAR steps to accelerate and optimize DX in digital partnership. It is a process that puts people first.

Before delving into the importance of Knowledge and how to achieve this DX transition benchmark, let's briefly revisit the ADKAR model. ADKAR stands for Awareness, Desire, Knowledge, Ability, and Reinforcement—five stages that guide effective change management.

While the first two stages (Awareness and Desire) set the stage for change, it's the Knowledge stage that bridges the gap between awareness and the ability to adapt to new technologies.

In brownfield projects and for construction in other challenging contexts, efficiency is not a destination but a continuous journey. Traditional project planning and execution would follow what can be thought of as a "left to right" workflow, which can lead to sequencing issues and other efficiency-stealing misalignments.

To address this issue, industry leaders developed the concept of Advanced Work Packaging (AWP), advancing Knowledge and aligning engineering, procurement, and construction to improve overall project performance. It flips workflow planning around, starting from the desired endpoint. This reverse engineering of sorts is designed for constraint-free execution and can be thought of, in contrast, as a "right to left" approach. Now considered an industry best practice for certain types of construction projects, AWP elevates mindsets through advocating for the use of supporting digital solutions to seek maximum construction efficiency.

Digital workflows, including work packages, materials management, completions and reporting offer significant benefits by reducing person hours, increasing efficiency, and saving both time and money through ensuring correct constraint-free sequencing as well as premediating (and correcting) problems before they occur. The adoption of an AWP methodology and digital tools in brownfield projects and other complex contexts, however, face unique challenges.

Brownfield projects, which involve existing facilities, pose distinct challenges in the uptake of digital tools and therefore stand to benefit significantly from working with experienced digital transformation consultants.

Brownfield projects – and other modifications, turnarounds and temporary shutdowns – often lack complete and up-to-date data that may require retroactive digitalization efforts. Operators may prefer paper-based plans over 3D models, which can complicate the adoption of digital tools on the ground.

In brownfield execution, the scope is often smaller and more piecemeal, with capital constraints yielding to existing methods and processes. Applying digital workflows in such projects may require adjustments and flexibility, which a seasoned digital partner is able to help navigate for maximum uptake and, hence, ROI.

To do so, a digital partner will educate users on how to adopt and adapt to the change.

Where the first two ADKAR steps (Awareness and Desire) apply to the status quo situation, Step 3, Knowledge, begins the transition phase in the ADKAR change management model. The challenges in adopting innovative processes and technology in brownfield construction and other modification or turnaround projects are multifaceted and include organizational, behavioral and cultural aspects. This is where the ADKAR model of Change Management becomes invaluable.

A digital partner accelerates the uptake of Knowledge for successful adoption of the digital tool(s), advancing the digital transformation strategy by helping to make training and material in different formats (online, written, person) available, consistent and easily accessible. The recommended actions follow to educate users on how to adopt to and adapt the change in question:

The right digital partner can also help with progress monitoring, which is an essential step to ensure advancement through the ADKAR steps toward successful digital uptake and scalability:

Digital transformation is the key to transforming the efficiency, safety and sustainability of construction execution. But the journey toward adopting new digital tools is not just about Awareness or Desire; it requires the empowerment of end-users through Knowledge. Digital tools exist that have revolutionized construction efficiency, but successfully implementing these tools, especially in brownfield projects, hinges on effective change management that is best approached in digital partnership.

By following the principles of the ADKAR (or similar change management model) and focusing on the Knowledge stage, construction industry stakeholders can bridge the gap between Awareness and Ability. Through diverse training formats, consistency, accessibility and progress monitoring, the workforce can be equipped with the necessary knowledge to embrace new digital tools. This, in turn, leads to safer work environments, fewer mistakes, increased efficiency and, ultimately, a more prosperous future for the construction industry.

As we continue to witness the transformative power of technology in construction, one thing is clear: Knowledge is not just power; it's the hinge on which DX success in construction execution relies.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

“Even the most advanced technology can’t achieve anything by itself. Value emerges as a combination of the tool and the people who operate it....

Read More

Read More

Change management frameworks can help identify barriers to the successful adoption of new technological solutions. The ADKAR model of change...