Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

3 min read

Lisa De Vellis, PE

:

Jun 3, 2022 11:43:22 AM

Lisa De Vellis, PE

:

Jun 3, 2022 11:43:22 AM

Following socio-political pressures towards net zero, the war in Ukraine has compounded the direct need to advance energy development. EPC contractors and owner-operators need facility design, construction, operation and maintenance systems that optimize output while minimizing impact. The future of energy rests at the interface of productivity, sustainability and innovation. That interface is where data-centric solutions, including technological tools and enabling partnerships, reside.

An effective digital transformation (DX) strategy harnesses the power of data to capitalize on key technological advances that prioritize efficiencies, and to facilitate partnership working towards interoperability and a more sustainable energy future.

This blog is two-part blog series:

To keep pace with demands for production, compliance and profit, facility design and construction as well as asset operation and maintenance is trending towards minimalism. Facilities of the future favor prefabricated components and modularity that reduce materials and installation costs.

Modern engineering of this nature increases automation and minimizes environmental impact. It’s a simple concept: less infrastructure means less maintenance, which means less waste. Assets on offshore rigs and vessels, as one example, require continuous inspection and maintenance in addition to regular repairs to ensure optimal performance. Through minimal construction, this is possible by capitalizing on a wide range of existing and emerging digital technologies.

Rooted in data, automation revolves around digital solutions such as facility and construction digital twins, drones, robots, advanced analytics, combined IT/OT (information technology/operational technology) platforms, virtual realities, mobile hardware and more. Take construction digital twins, for example. Digital twins deliver virtual realities for running simulations. With fidelity to the real deal, users of construction digital twins can help strategize approaches, prepare for worst-case scenarios, as well as optimize people, workflows and processes.

Amid all the cutting-edge technology, the digital twin is at the tip of the spear. Construction digital twins are poised to dominate the future landscape across asset lifecycle from design to construction to maintenance. Innovations of this ilk rely on accurate and comprehensive data capture to simplify construction, processes and workflows.

This ability to remotely visualize, monitor and operate physical assets unsurprisingly manifests in eighty-nine percent of companies believing that digital twin strategies will transform their approach to operational excellence.

With the ability to optimize design, manage supply chains, conduct predictive maintenance and more, digital twin technology is powered by data. And so, the data must be trustworthy and system-ready. This data is pre-existing in the form of design schematics, component specifications and regulatory protocols, for example.

To harness the potential of emerging trends such as construction digital twins, this information must be reliably and consistently captured in digital format. It must be complete, accurate, formatted, usable and accessible. System-ready data enables operational efficiencies that directly translate into environmental impact.

The energy sector, namely oil and gas, faces lots of uncertainty from geo-political turmoil and environmental pressures alike. But the data-driven energy transition offers practical tools for forward-thinking businesses to pursue sustainability that is more substance over form.

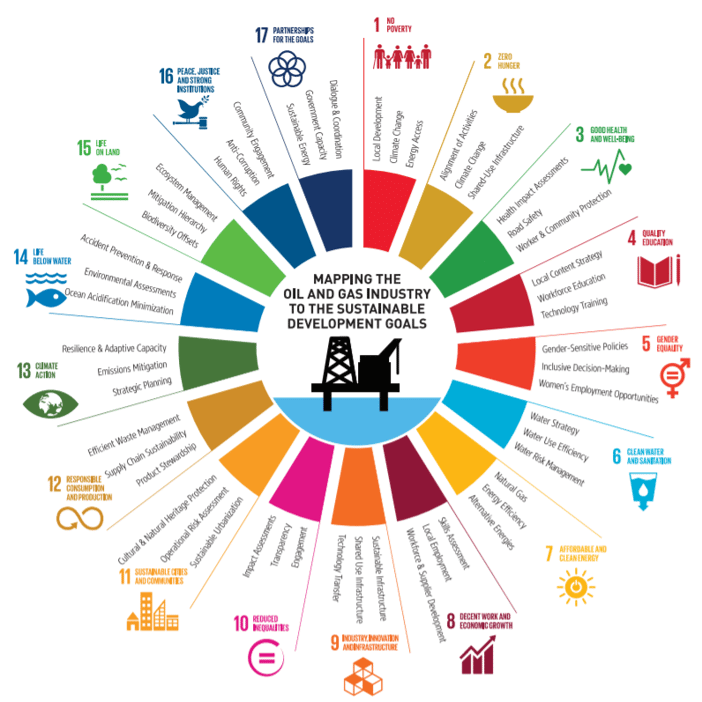

The global community is rallying behind the seventeen Sustainable Development Goals (SDGs). The energy sector, by way of facility design, construction, operation and maintenance is poised to contribute positively to the SDGs through intelligent data capture and use.

Investing in research and development advances data-dependent technologies so that construction, operations and maintenance can be managed in a way that honours all three pillars of sustainability: environmental, economic and social. Modernizing the energy sector through data-driven technological advances increases operational efficiencies with direct decarbonization impact.

Data-driven solutions reduce downtime and minimize instability, reducing intermittent flaring and venting upstream. In fact, optimizing operations holds the key to ninety percent of “known technological solutions to decarbonization”. Asset integrity management, for example, minimizes rogue emissions.

Matthew Bell, Chief Product Officer with MODS, speaks to the importance of data in asset integrity management:

“Data-driven systems and processes ensure that you have reliable, accurate and consistent information throughout the lifecycle of your asset. With the right digital systems in place, this information is easily accessible, providing access to quickly analyze, predict, and schedule maintenance at the right time. Conventional systems lack the control, history and visibility that data-driven systems provide. All of this leads to a more efficiently run asset, driven by data, so that you can avoid unplanned downtime and, in turn, escalating costs.”

The data management component of a DX strategy cannot be underestimated. It powers all systems and processes, which in the future will be increasingly integrated. The future is agnostic. Systems integration and compatibility, as well as increasing standardization of protocols and best practices allows for more rapid uptake of progressive technologies. But all of this relies on data.

Software solutions such as Advanced Work Packaging ensure environmental compliance through operational oversight and user-friendly, accurate reporting features that enable businesses to understand and communicate operational impact. When data is managed as a single source of truth, communications with all stakeholders, from government to client and subcontractors is made simple.

Sustainability, defined in the context of the globally endorsed SDGs, can be at the heart of every process, every workflow and every business decision. Robust environmental strategies rely on continuous monitoring and evaluation, which requires data capture from sensors. Digitization and more advanced digitalization technologies including sensors and facility digital twins form part of the sustainable solution.

The key enabler of data-driven advances in the design, construction, operation and maintenance of energy and other industrial facilities revolves around partnerships. DX partnerships enable global collaborations through collecting and managing data, making it system ready.

The second post addresses data integrity through  , which are essential to ensuring DX success.

, which are essential to ensuring DX success.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

This blog is the continuation of Data-driven smart facilities and decarbonization towards a sustainable energy future.

The Global Pandemic has brought with it, death, devastating life changes and a myriad of workplace changes. The Energy industry did not escape the...

Many industrial-sector concerns revolve around communication silos where information is stored and sometimes obscured from other teams working on the...