Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

2 min read

Lisa De Vellis, PE

:

May 9, 2023 11:07:34 AM

Lisa De Vellis, PE

:

May 9, 2023 11:07:34 AM

“If you build it, they will come.” So goes the famous line from Field of Dreams. As charming the sentiment is, the global fabrication market disagrees. Instead, as the market dictates, when they are coming, you must build it. It’s the old supply-demand paradigm. And, fortunately for suppliers, demand for metal fabrication is increasing. In an otherwise grim economy, the fabrication outlook is bright indeed.

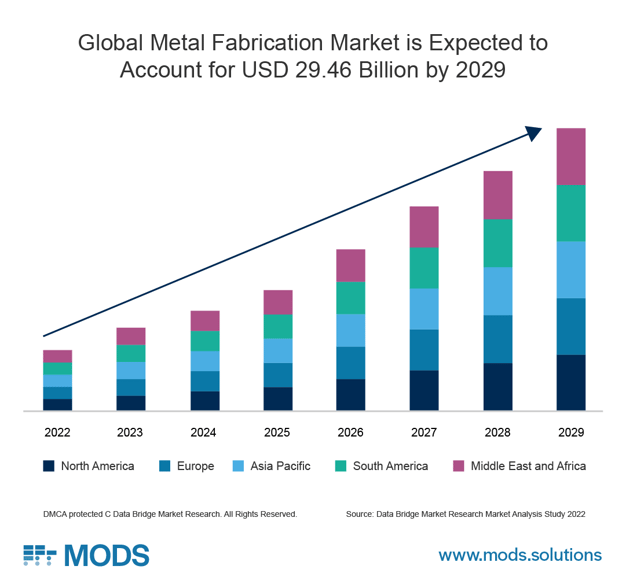

The global metal fabrication market was valued at USD 20 billion in 2021 and is predicted to reach nearly USD 30 billion by 2029, following a CAGR of 4.7%. Considering the end-users of fabricated metals, the construction industry dominates around 37% of the fabrication market share. The Oil & Gas (O&G) industry occupies a large chunk of the fabrication market, as well, with around one-quarter of the global fabrication production destined specifically for O&G Assets. With the Floating Production Storage and Offloading (FPSO) market expected to reach USD 17.3 billion by 2027, as only one example, the opportunistic fabrication market outlook is no surprise. Setting construction and O&G aside, the remaining end-user market can be segmented between other industries such as aerospace, automotive, marine and military.

Geographically, there is a fairly even distribution of the fabrication market around the world, as shown below:

Certainly, the fabrication market is driven largely by market forces of the end-users – including the increasingly global demand for prefabricated structures in construction – as well as availability of the raw materials; and its trajectory may be impacted by any geo-political constraints that may disrupt market forces.

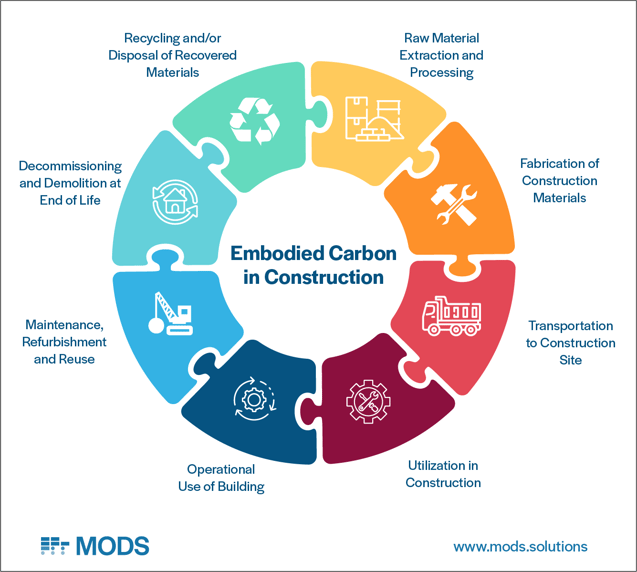

How fabricators manage their processes locks an energy-use and greenhouse gas emissions history into their fabricated components. This is part of what’s referred to as embodied carbon:

Given the massive environmental footprint of fabricators’ end users – from construction to O&G to automotive – there is increasing pressure to decarbonize materials used in their sectors. A material’s carbon embodiment is established upstream in the value chain by the fabricator. This means that the fabricator has an impetus to supply its end users with materials boasting lower carbon embodiment.

For fabrication companies to keep pace with the growing market demand, to maximize their market share, and to attract the growing contingent of end users seeking decarbonization, they need to modernize. One way to do this is through the adoption of available digital technologies. To that end, fabrication businesses can now join the digital revolution in the adoption of paperless, digital processes to oversee everything from the procurement of their raw materials, through work processes required to transform the raw materials into components and to transport and logistics of getting the finished product to the end user.

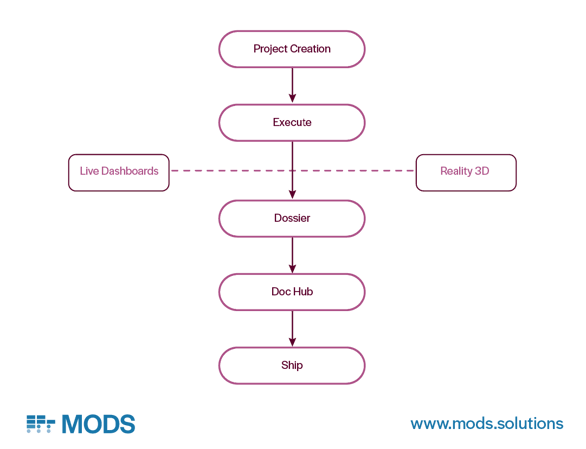

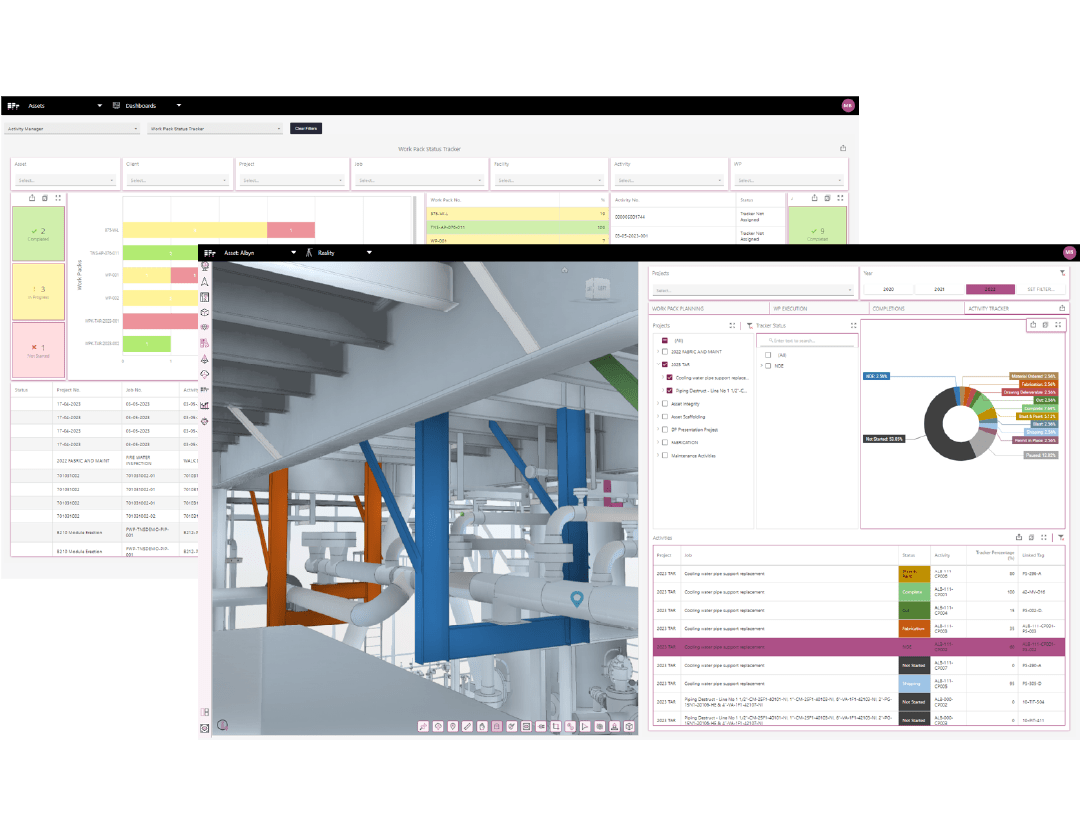

Digital fabrication software transforms the way fabrication processes are managed and overseen, delivering quality-assured, traceable components that meet both schedule and budget expectations. Through live dashboards and with the option to be used as part of an Asset visualization data hub, Fabrication software can track the entire materials value-and-supply chains from project creation through shipment (and, in the case of MODS software, through construction, O&M and decommissioning with systems alignment between the Owner-Operator and Fabricator).

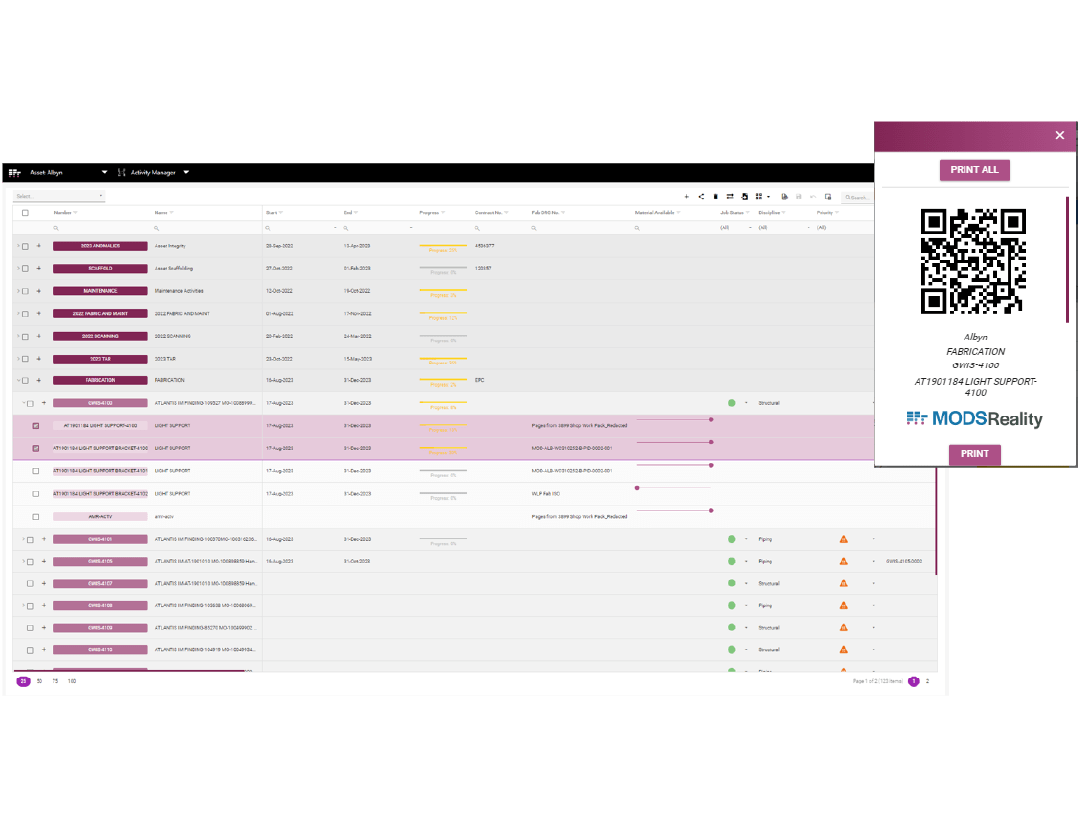

Through the use of unique QR codes, users can manage project activities and materials therein:

Live dashboards can be used to create and track stages and activities, as well as to conduct technical queries with ease:

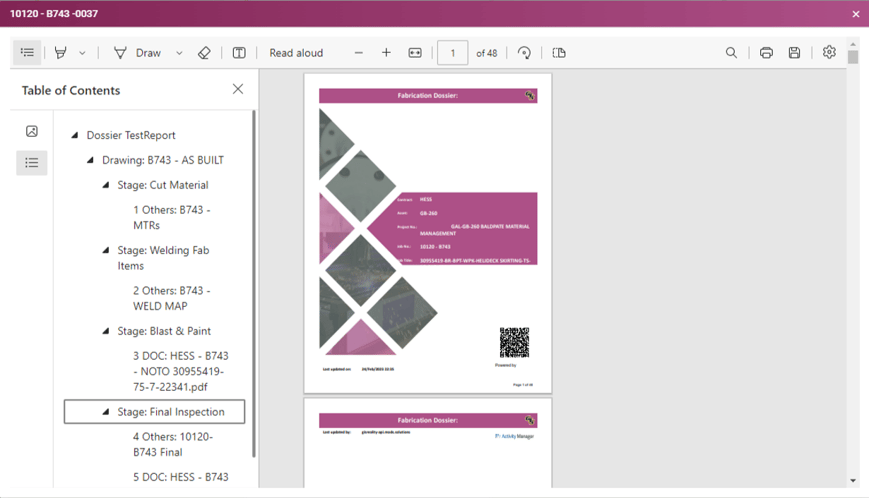

Paperless dossiers save time with digital sign-offs:

With the ability to automatically create fabrication dossiers complete with all sign-offs and additional documents such as drawings and specifications, as well as to easily report status in both 2D and 3D via a suite of interactive dashboards, digital fabrication software can transform fabrication processes, benefitting both the fabricator and end-user alike.

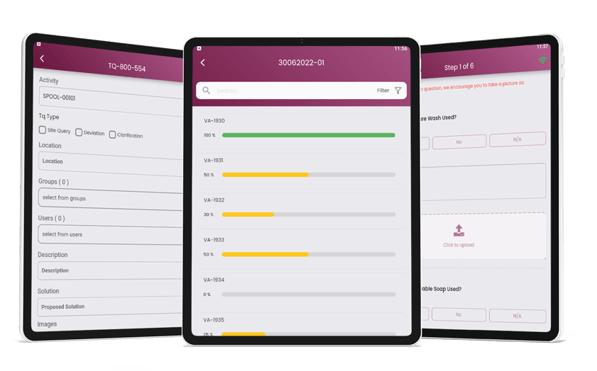

Further, mobile functionality enhances ease of use for project staff and managers, and enables full digital integration of businesses via mobile and web applications:

With digital systems in place, the end user can inherit a comprehensive materials database from their fabricator(s), ensuring the fullest digital history possible to quality assure their own processes, construction or otherwise. Such digital solutions can help fabricators maximize the potential of the booming global fabrication market because digital technology can breathe new life into industrial fabrication.

If your fabrication business is ready to join the industrial revolution, check out  software solution.

software solution.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Today, MODS announced the release of a new software solution that enables fabrication contractors to enter the digital revolution. Breaking ground,...

“The more you build, the more you’re going to learn.” Lee Anthony Bordelon Sr certainly knows. He’s been with GIS – a strategic partner in global...

Picture the scene. You are a Construction manager in the Energy Sector, and you desperately need more resources to complete your project. The first...