Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

3 min read

Lisa De Vellis, PE

:

Mar 10, 2022 2:10:57 PM

Lisa De Vellis, PE

:

Mar 10, 2022 2:10:57 PM

"Insufficient facts always invite danger.” – Dr. Spock

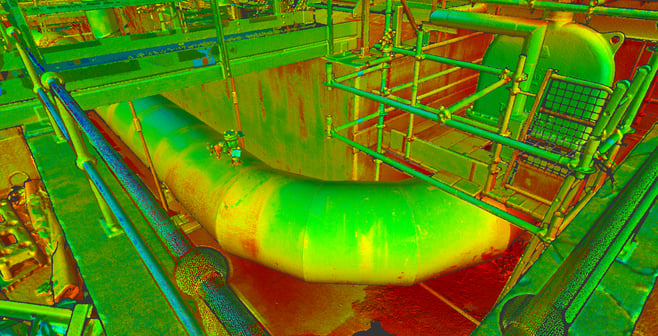

Much in the way a still-life artist records the contours of an object with her pencil, a laser scanner records spatial 3D data of an asset or assets. In the form of point-cloud data, laser scanners create a fact-based dimensional reality in digital form.

Laser scanning obliterates the need for paper-based drawings or schematics, which can be misread or may not reflect the updated as-built reality. The lack of reliable updates on paper plans is precisely the sort of insufficient fact base to which Spock alludes. The absence of accurate and complete information renders optimal decision making impossible.

Where the artists pen is like the laser scanner, recording the object’s lines and volume, the artist’s eye is the dimensional control, measuring distances and proportions so that the pen records the subject’s surface with accurate measurements and proportions.

Accurate as-built imaging allows desktop planning of modifications, maintenance and of quality checks between design data and onsite reality. Three-dimensional laser scanning generates these reliable as-built records throughout the asset lifecycle or as often as needed.

The advanced surveying technique dimensional control works in tandem with the 3D laser scanning to record accurate dimensions, ensuring that the as-builts reflect the reality both in terms of spatial arrangement but also in terms of actual measurements.

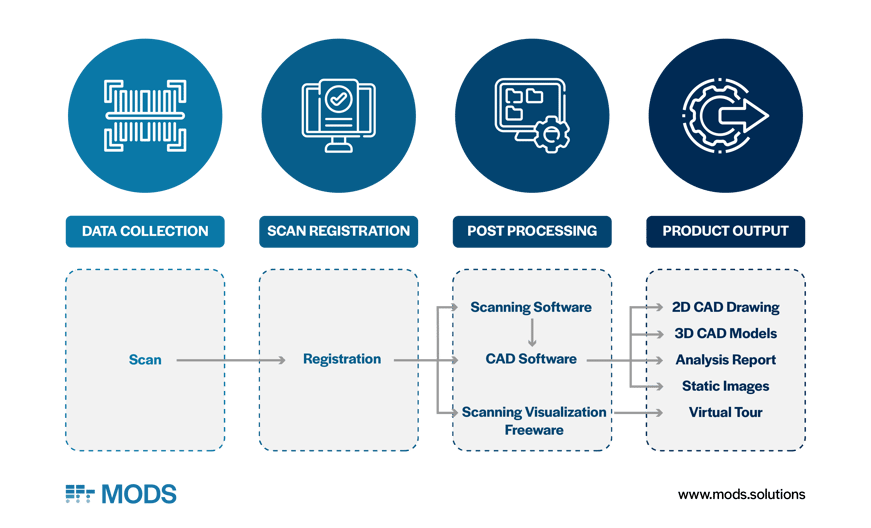

Together with dimensional control, laser scans generate point-cloud data that specialized software uses to create a 3D model of the facility, area or asset. Laser scans collect data that is processed by software and converted into useful outputs. These product outputs are the images and models with which the engineer, manager or other user interfaces.

Such 3D models lend efficiencies and ease to the design of new piping or other components because the dimensional design space is clear.

As per the wise words of Spock, fact-based working has safety implications, too. Laser scanning and dimensional control remove room for interpretation: spatial information is complete and obvious, meaning that people can anticipate and avoid potential hazards including unnecessary downtime owing to incorrect calculations, or the reduction of hot work on a live asset.

The specific benefits of 3D laser scanning and dimensional control are wide ranging. When used with sophisticated software solutions, the suite of realized benefits includes the following:

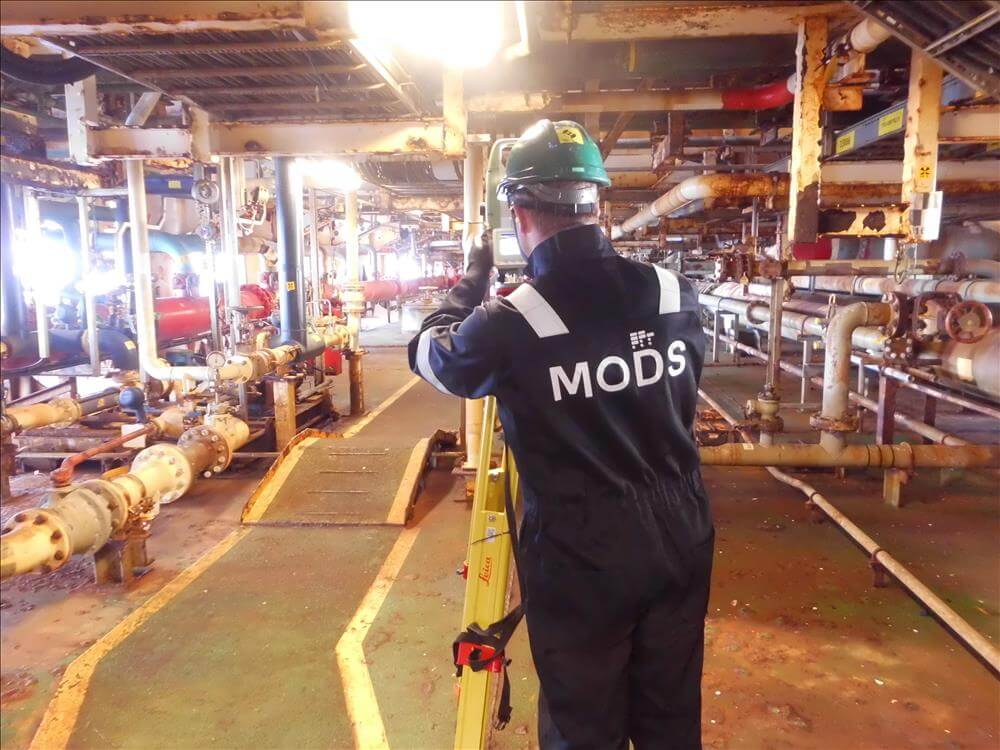

Andy Wilson, Dimensional Control Manager at MODS brings perspective as to the human element of laser scanning capabilities. Such techniques are well and good, and with powerful software able to convert raw point-cloud data into accurate models, it’s always important to bear in mind that the output is only as good as the input.

“Anyone can buy a scanner and push play,” says Andy, “but as my experience has proven, a surveyor’s mindset and experience can often see things others cannot."

What Andy means is that hardware tools such as laser scanner still require human inputs, and those human inputs must be informed and of a specialist mindset in order to accommodate the nuances of each use-case scenario. Surveyors like Andy are the artists in the equation, ensuring that the measurement techniques and controls are accurate and quality assured.

Andy continues:

“MODS have been providing dimensional control and laser scanning services since 2002. Over this time we have developed effective procedures that optimize the planning and execution of projects of all sizes worldwide. We are all experienced dimensional surveyors and we, like the rest of us in this profession, started out with theodolites [which are old-fashioned surveying instruments].”

Theodolites, which have a rotating telescope for measuring horizontal and vertical angles, date back to the 16th century and are a far cry from the Vulcan mindset that champions change, creativity and innovation. Digital data-driven solutions, such as software that works in conjunction with 3D laser scanning, are the future.

Advanced software solutions used for things such as construction execution of industrial or other complex facilities employ features including QR codes. QR codes associated with scanning targets contribute to 3D model data, identifying and tagging items.

Particularly in the construction of facilities that house complex processes such as those in the energy sector or industrial manufacturing, working from accurate, comprehensive and reliable as-built information makes for a successful project.

Even digital as-builts, however, are only as good as the quality of data. But with 3D laser scanning, dimensional control, specialized software and experienced surveyors, the digital 3D models are a fact-based dimensional reality – an art marrying on-the-ground truth with innovation.

Andy, whose life as a surveyor revolves around making fact-based information understandable and useful, would make Dr. Spock proud:

“Taking the data one step further and maximizing its potential, is to adopt a tailored software. Then, you really have the power to control asset life cycle, mitigate risks, enhance efficiencies, link in associated documents and reports, and ultimately rein-in costs.”

To learn more about how laser scanning and dimensional control can help you, contact one of our  .

.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

‘Laser scanning and Dimensional control’ – could be mistaken for an episode of the well-known series, ‘Star Trek’. The informed Energy sector reader...

Whether it's a complex level problem in your plant or a single defect in a piece of equipment, the ROI delivered to Operators by completing projects...

As the world is rapidly advancing into the 4th industrial age, Oil & Gas continue to remain essential to the energy sector and a key enabler for the...