Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

2 min read

Lisa De Vellis, PE

:

Aug 18, 2022 12:24:08 PM

Lisa De Vellis, PE

:

Aug 18, 2022 12:24:08 PM

Petrofac designs, builds, and operates world-class energy facilities engineered for safety, optimal efficiency and low emissions. MODS partnered with Petrofac in January 2020 to remove manual processes from their brownfield development projects.

Petrofac, is a leading provider of services to the global energy industry. Boasting 200+ major projects in upstream O&G, refining and petrochemicals as well as in the new energy sector. Working across a range of markets and entire asset life cycles, Petrofac requires agile solutions to address the inherent complexities of brownfield development.

Owing to the industry’s historic reliance on manual systems to manage complex construction processes, a major goal is to ensure project information remains intact, comprehensive, correct and accessible. Petrofac recognized this opportunity to pioneer the use of digital in the UKCS brownfield sphere.

Petrofac prioritizes information management, which is particularly challenging in brownfield contexts. Therefore, their overarching objective in partnering with MODS was to capture all data in one system.

This, Alex Robertson, Petrofac’s Digital and Innovation Senior Manager, says,

“gives us the ability to be more efficient, removing manual processes, including labor required to process information, all in one environment.”

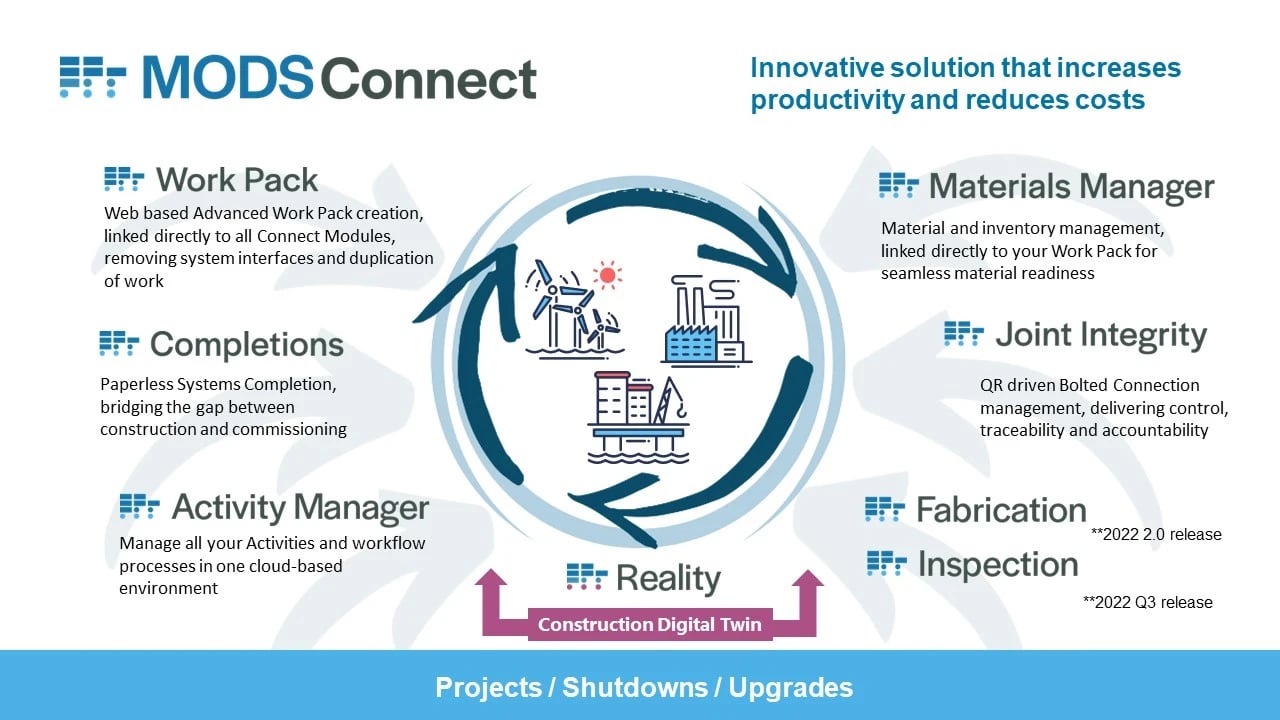

MODS Connect, a cloud-based software, was the digital solution for Petrofac’s UKCS brownfield projects. Compatible with Petrofac’s existing systems and processes, Petrofac’s use of MODS Connect decreased administrative burdens to improve efficiency, reducing time and effort by 50 percent.

Remotely accessible by anyone from anywhere, MODS Connect enhanced Petrofac’s ease of communication, delivering project transparency with internal and external stakeholders for a variety of brownfield projects. MODS Connect enabled Petrofac to harness the power of digitization and visualization through the following: MODS Connect WorkPack, MODS Connect Completions, MODS Connect Materials and a progress tracking feature.

MODS Connect integrated with Petrofac’s existing systems. Ryan Thom, Petrofac's Lead Analyst- Business Applications, says,

"[This] provides us the ability to deploy & startup projects efficiently, onboard users and seamlessly integrate with other tools in our ecosystem".

Minimizing overrun, keeping projects on time and on-or-under budget, MODS Connect enables remote project oversight, objectively managed workflows, full transparency and comprehensive project archives. MODS Connect aligns people, processes and technology, setting the stage for a successful digital transformation strategy.

Petrofac is using MODS Connect for “connected delivery.” This software solution, Alex says,

“provides a connected digital platform between the four systems [Materials Manager, Work Packs, Completions, and Progress Tracking] and our site-based workforce.”

Replacing traditional reports with real-time performance dashboards reduced 50 percent time and effort required to provide clients with key project data. Project transparency through the remotely accessible digital models enabled informed decision making, anticipating and avoiding common pitfalls. And high volumes of diverse brownfield modifications were delivered on time and within budget using MODS Connect.

Alex says of the benefits:

“[With MODS Connect] we have standardized what ‘good’ looks like and we have the flexibility to meet client-specific requirements. We can record all information that goes into the system and measure and monitor data in a consistent manner so we can be very confident that what we report is accurate. Progress and photographs are at the click of a button. The accuracy is a very important point, the tools allow the folks in the field to trust the information coming to them to quality check.”

Check out the  for digital brownfield solution we've provided to Petrofac. We've talked about the problem Petrofac was facing, the solution MODS provided them and three different projects they've used our software.

for digital brownfield solution we've provided to Petrofac. We've talked about the problem Petrofac was facing, the solution MODS provided them and three different projects they've used our software.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

Granite City business continues to support Aberdeen Ladies FC

Today, MODS announced the release of a new software solution that enables fabrication contractors to enter the digital revolution. Breaking ground,...

In a technology partnership Grand Isle Shipyards with MODS has been providing Commissioning and Integrity services to the energy industry for the...