Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

The future of the energy sector rests at the interface of sustainability, adaptability and innovation.

With massive socio-political pressures towards net zero, the war in Ukraine has compounded the dire need to advance energy development. Increasing construction productivity while reducing impact ought to inspire new ways of working for EPC contractors and owner-operators to remain viable in today’s world.

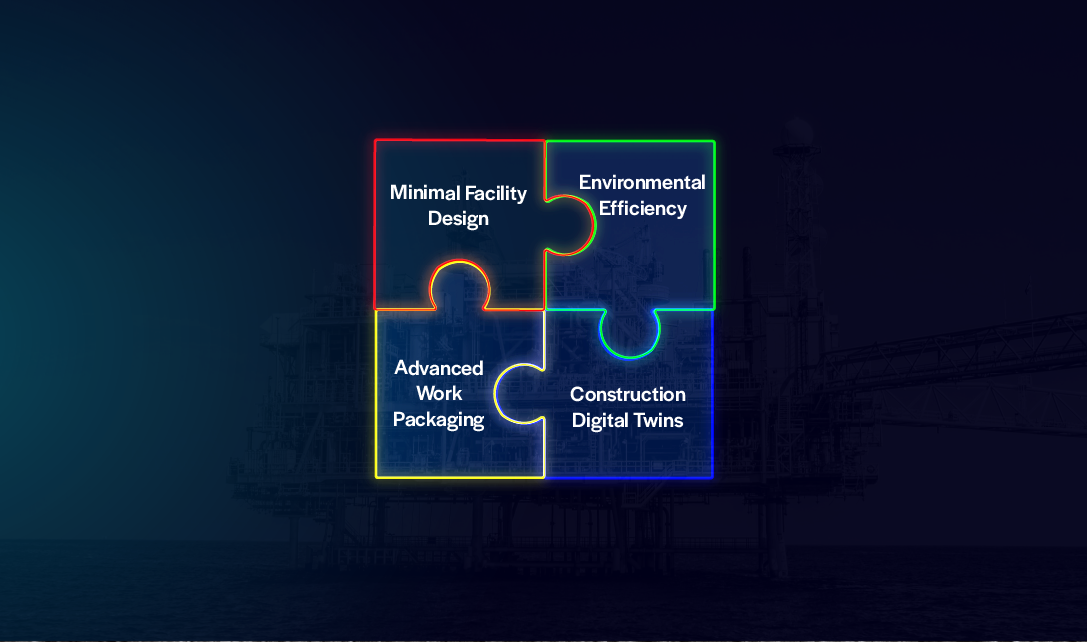

This blog series addresses four energy-sector development trends that cannot be ignored:

Sustainability pressures, from popular and governance sources, drive energy-sector development today. Increased compliance restrictions, working under the microscope of popular opinion and juggling social capital with financial outcomes challenges both greenfield and brownfield energy-sector development.

Environmental efficiency is not only a future trend but should be obligatory. The goal is to reduce pollution while maintaining the same or improved levels of economic production and growth.

The energy transition and Industry 4.0 demand EPC contractors and owner-operators reduce construction footprints. Digitizing systems and workflows streamlines processes with software solutions like Materials Manager, Activity Manager and Work Pack keeps schedules as short as possible. Shorter construction schedules translate to less resource waste.

Software solutions phase out paper-based systems, reducing manual intervention and informing decision making. Digital materials management, work packs and progress tracking make brownfield projects manageable, keeping projects on schedule and under budget.

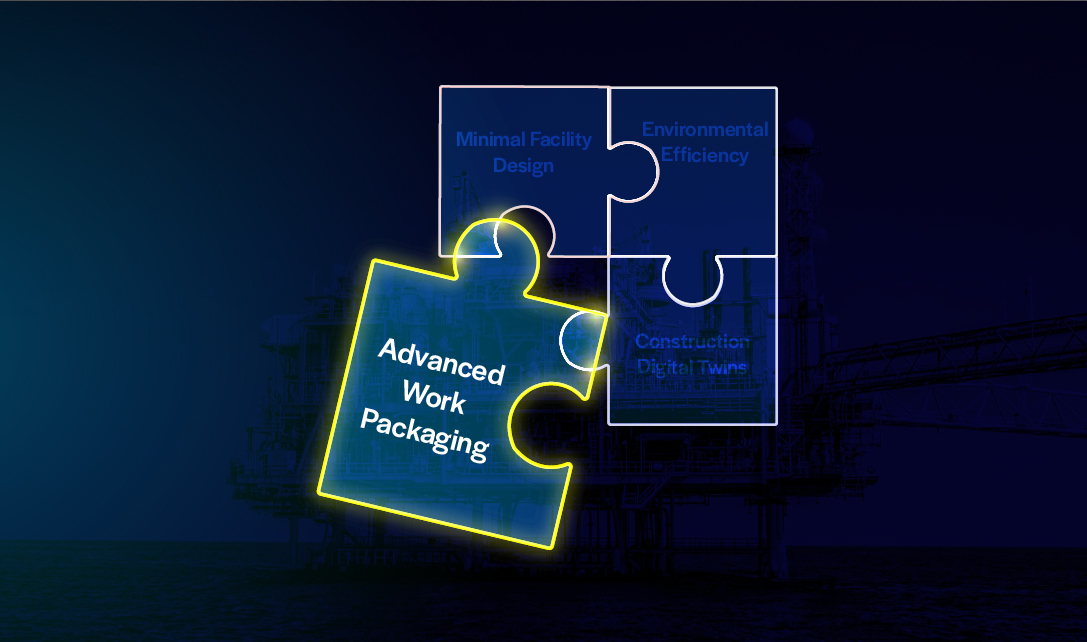

When it comes to greenfield development, top EPC firms headline trends, capitalizing on the power of Advanced Work Packaging (AWP), which reduces financial and resource waste and, hence, reduces projects’ carbon footprints.

To read more about this trend, check out the full post: Environmental Efficiency: A Future Trend for Energy Sector Facilities

One of the biggest challenges in the construction of capital facilities is keeping projects on time and under budget. Digital AWP solutions ensure the proper sequential execution of tasks. Without this in place, industrial greenfield development projects face 25 percent cost overruns and 33 percent schedule overruns.

According to ASI Group:

According to ASI Group:

“AWP is a global best practice being used by some of the leading companies in the world and has been found to improve safety (0 incidents in optimal cases), reduce costs (up to 10% TIC reduction), reduce rework (in some cases down to 0), shorten schedule and improve project predictability.”

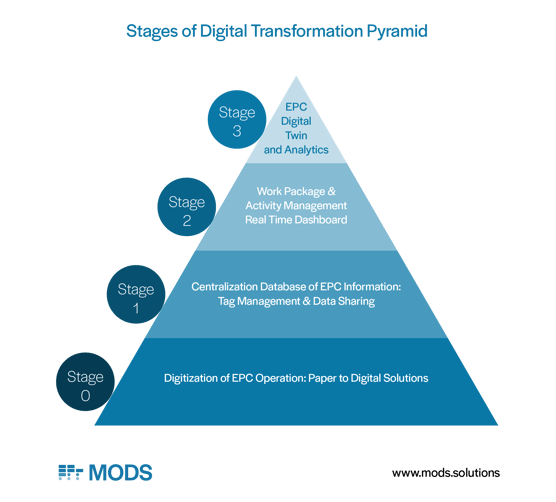

AWP is part of a broader digital transformation (DX) journey in the construction of energy and other complex industrial facilities. Once a DX strategy is conceptualized, committed to and commenced, AWP is a powerful step for energy facilities to maximize environmental efficiency.

Energy facilities of the future will further benefit from improved design, which is the third future trend discussed in this series. The cumulative effect of digitization, of more sophisticated digitalization approaches to working, and of minimal facility design address the sustainability push, making for modern and competitive businesses.

To read more about this trend, check out the full post: Advanced Work Packaging (AWP): Future Trends in Energy Sector Facilities

Facilities of the future will rely on digital technology including drones, robots, advanced analytics, combined IT/OT (information technology/operational technology) platforms, virtual reality, mobile hardware and more. Key enablers of future facilities are likely to revolve around conditions monitoring, equipment optimization, onshore engineering support using virtual 3D models and assisted worker mobile technologies.

Such innovations sound (and are) technologically advanced, yet they simplify construction, processes and workflow. Facilities of the future favor prefabricated components and modularity, reducing fabrication and installation costs.

Plus, more infrastructure implicates higher maintenance requirements; the push to reduce this is economically and environmentally favorable. There’s even a move towards unmanned offshore platforms, a previously unheard of concept that capitalizes on the wide range of existing and emerging digital technologies.

Facilities of the future will trend minimal, benefiting from full digitization and especially on the more advanced digitalization methods as DX journeys progress. Modern engineering of this nature increases automation and minimizes environmental impact.

To read more about this trend, check out the full post: Minimal Facility Design: A Future Trend in Energy Sector Facility

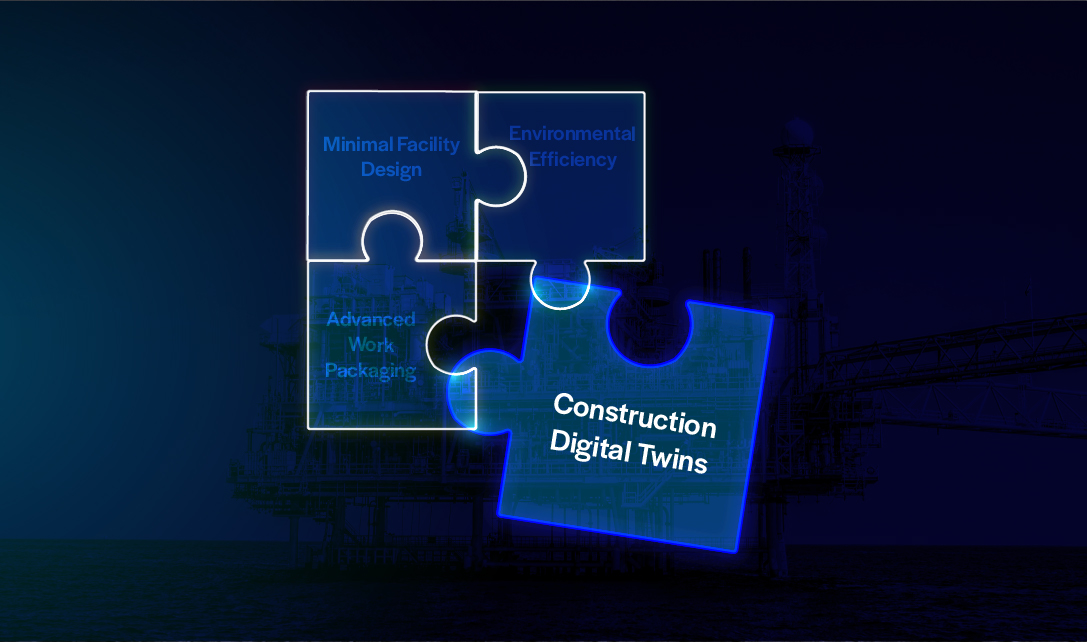

With increased automation and drivers at the interface of economic, operational and environmental efficiencies, virtual realities such as digital twins create digital environments in which users can run simulations to strategize, prepare for and optimize people, workflows and processes, as well as IT and OT systems.

Virtual or mixed reality is the use of computer hardware and software to create an artificial environment by providing a virtual world for users to immerse into or by overlaying information on top of the real world for users to see and interact with. This can be used for engineering and operational/maintenance support purposes.

Amid all the cutting-edge digital technology, the digital twin is at the tip of the spear. Digital twins are poised to dominate the future landscape across every aspect of the asset lifecycle. Digital twins, however, rely on a form of machine learning. As facility and asset design modernizes, trending towards increased universality and standardization, digital twins will become easier to train.

Technological advances feed other technological advances in positive feedback loop that will take the energy sector further into the digital future, promoting sustainability, responsiveness, safety and a host of other benefits.

To read more about this trend, check out the full post: Construction Digital Twins: A Future Trend in Energy Sector Facilities.

Commitments to sustainability and reducing the environmental footprint drive future trends in the energy and other industrial and/or manufacturing sectors. AWP, with its automated functionalities, take digitized processes and advance them to effect real change in the execution of greenfield development. Modernizing facility design is the next step through modularity and automation that uses a wider-range of technologies, including hardware, software and machine learning solutions. Minimal, automated facility design, in turn, is increasingly possible through the power of the digital twin.

This blog series explores each of these four future trends in more detail. Check out each topic below:

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

This is the final blog in our four-part series addressing the following energy-sector development trends:

This blog is the second in a four-part series looking at the following future trends in energy sector facilities:

This blog is the third in a four-part series looking at the following energy-sector development trends: