Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

3 min read

Lisa De Vellis, PE

:

Jul 6, 2023 8:30:00 AM

Lisa De Vellis, PE

:

Jul 6, 2023 8:30:00 AM

Recipients of a recent Advanced Work Packaging (AWP) project award, JGC are no strangers to headlining the digital transformation (DX) of complex industrial projects. The significant JGC Group have committed to meeting challenges for a better world through its engineering, procurement and construction (EPC) business one project at a time. They have been doing so, to great effect, through digitizing information and digitalizing workflows for improved construction execution efficiencies.

JGC strive to “enhance planetary health.” This is pursued, in part, through their construction execution arm by implementing a robust DX journey that prioritizes sustainability. As their EPC business operates largely in industrial sectors that aren’t exactly known for their digital maturity, this is a laudable and progressive goal.

Global construction has a significant impact on the planetary health that JGC care about and, as such, they are well-placed to mitigate construction-related emissions. Streamlining workflows, in short, reduces energy inputs and minimizes embodied carbon of materials and Assets, both of which reduce the environmental footprints of built structures and industrial sectors.

JGC’s reform to accelerate sustainability-related digital transformation in construction execution was distilled into 5 overarching goals:

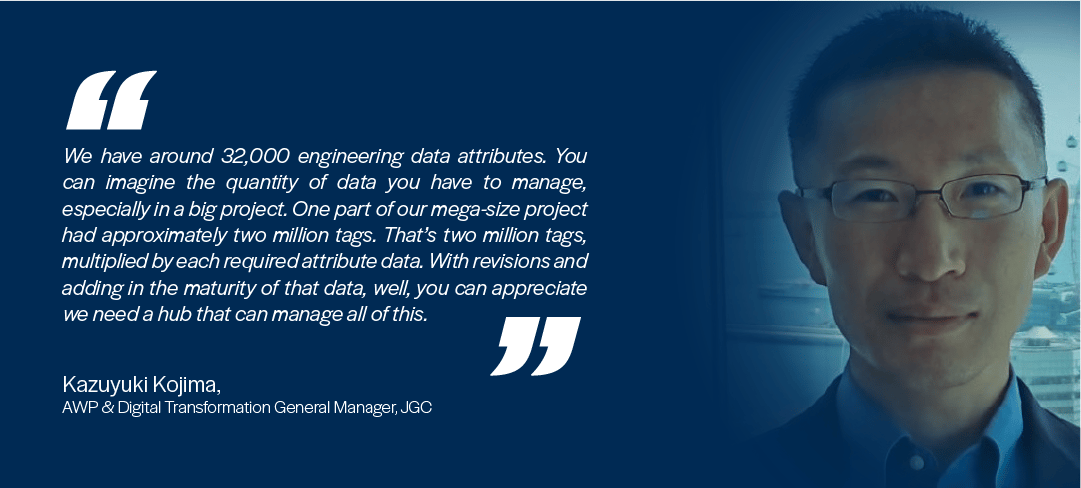

Owing to the scope of JCG’s EPC projects and portfolio at large, a digital system robust enough to manage swaths of Asset and project data was non-negotiable. A centralized system that acts as a single source of truth via the cloud ensures that project teams have access to the same, real-time information from both site and office.

The importance of data access, and ease of access, cannot be underestimated. It allows for constraint-free planning, in advance, following AWP principles that focus on efficient pathways to goal through left-to-right workflows.

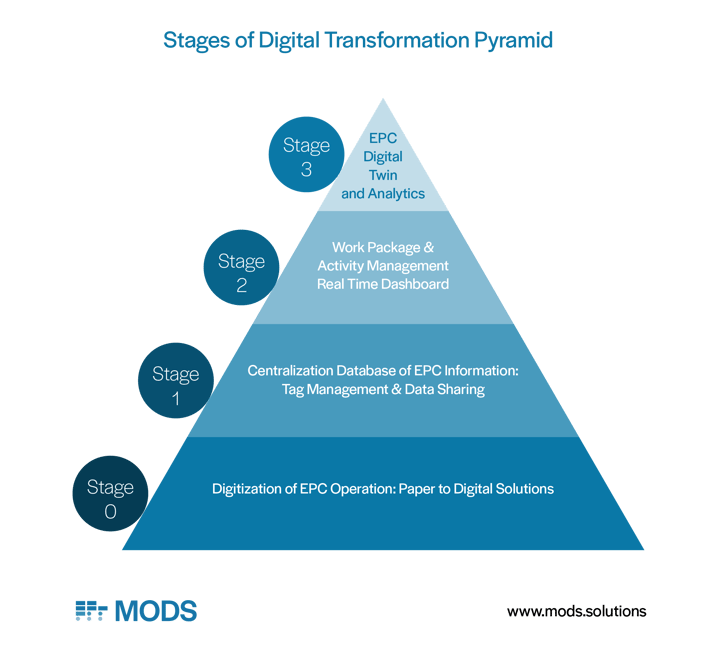

JGC’s EPC DX strategy followed a pyramid approach, as follows:

This stepwise process started with the foundational digitalization of information. Simply: they began to eliminate paper from their key project workflows such as work packs, opting instead for the ease and functionality of centralized cloud-based software. Upon being collated into a centralized EPC database for sharing, JGC next focused on tag management.

The benefits of JCG’s digitally transformed EPC construction execution were measurable and impressive. Onboarding a centralized single source of truth to enable remote management of their construction workflows resulted in the following:

JGC’s pyramid DX approach adopts increasing levels of sophistication, allowing both end users and the organization at large the time and resource to adapt to new ways of working. A solutions-based approach such as this is a good idea, particularly for complex projects and when teams are entrenched in ways of working. Bringing on piecemeal solutions that address one problem at a time such as managing materials or streamlining work packs generate a bit of momentum without overwhelming people with change.

Changing minds on the ground, convincing people to embrace emerging technologies and methods as the new de facto standard, is a notorious stumbling block in the adoption and upscaling of DX in EPC settings and, arguably, in any DX endeavor. JGC's stepwise approach gives workers time to adjust, as well as time to experience the newly realized efficiencies in their workflows and, hence, in their enhanced performance. It is then that workers become agents of change, enabling the uptake of new software solutions in a way that pave way for upscaling toward continuous DX.

For help at any stage in your DX journey,

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

A significant global contributor to economic growth and industrial development, JGC Group is an engineering, procurement and construction (EPC)...

It’s viral. Digital transformation (DX) is an increasingly essential journey for businesses, systems and processes to either embark on or accelerate....

The two-day Advanced Work Packaging (AWP) North America conference in Houston on 17-18 October revolved around daily themes of Improving Project...