Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Robert O’Connor, MODS’s Completions Manager, is a man of few words. But every word he says matters. This is a critical trait for someone who specializes in the handover phase of projects, where succinct communication drives perceived and, often, actual, success of the project.

Starting as an electrical technician working offshore at the age of twenty-two, Rob travelled the globe for fourteen years, living and working in Norway, Japan, South Korea, throughout the UKCS and other places. He has a no-nonsense sensibility that seems to have arisen from a young adult life bouncing around between different cultures, riding on a developing expertise in the completions phase of project execution.

With an electrical background, Rob worked his way up as a young man to electrical foreman for significant projects BG Armada, ConocoPhillips Britannia Satellite, Shell Leman Alpha, before turning his hand to working on the completions phase.

As Completions Coordinator with major clients including Shell, BP and ConocoPhillips, Rob worked on the likes of BG North Everest, Nexen Buzzard and BP Clair Ridge. His role was to ensure a smooth and efficient completion and transfer of responsibility for Hydrocarbon and Non-Hydrocarbon platform systems, from construction to Operations.

“The biggest challenged faced during completions,” says Rob, “is to ensure that the consistency and quality of records is maintained to a high standard during peak-time and critical aspects of the project. Ensuring this gives the client assurance that the technical integrity of the project has been achieved and minimises the number of challenges faced when bringing the asset back online or starting for the first time.”

Having joined MODS in July 2019, Rob was placed in charge of MODS Origin Completions and MODS Connect Handover modules, the prior working closely with partners JGC. At the time, MODS Origin was, well, at its origin.

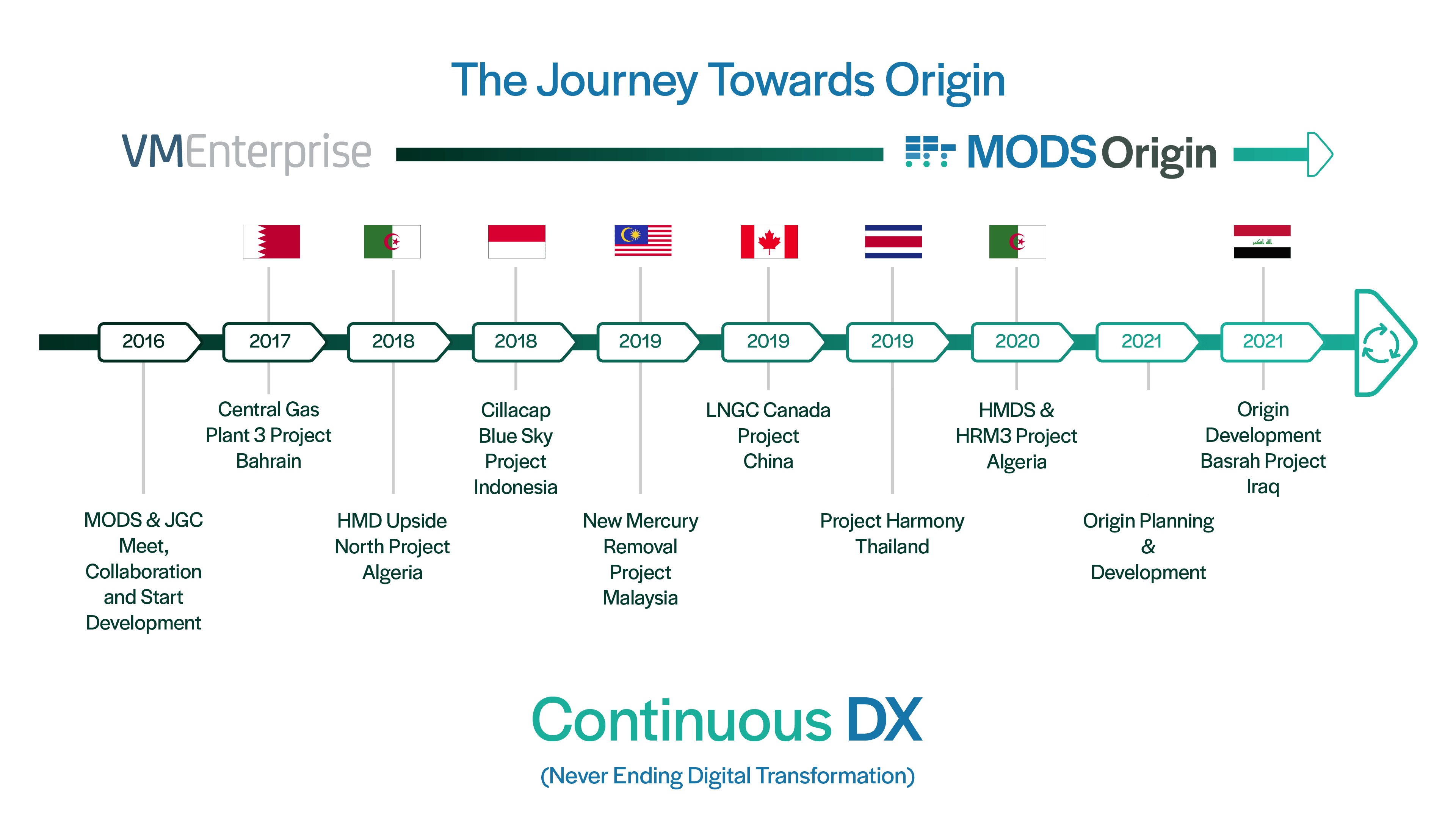

Evolving from its primordial version, Virtual Manager (VM) Enterprise, MODS Origin was developed to address JGC’s greenfield needs with Project Harmony in Thailand. Project Harmony was JGC’s first project with MODS and Rob took on this account to adapt JGC’s early digital transformation processes.

In 2018, well before becoming a major shareholder in MODS, JGC was awarded a major contract for the construction of synthetic resin-manufacturing chemical plants in Thailand. JGC formally joining forces with MODS was a game-changer with regards to the development of VM Enterprise into MODS Origin, which evolved to address in JGC’s EPC business challenges in the construction execution of greenfield and other mega-projects in the energy sector and beyond.

Having headlined the construction of over 20,000 projects in over 80 countries, JGC’s Project Harmony offered a prolific litmus test for the new MODS Origin. The Project Harmony scope included the whole shebang: engineering, procurement, construction and – Rob’s specialty – commissioning. He couldn’t have had a more capable environment on which to hang the genesis of MODS Origin.

Having headlined the construction of over 20,000 projects in over 80 countries, JGC’s Project Harmony offered a prolific litmus test for the new MODS Origin. The Project Harmony scope included the whole shebang: engineering, procurement, construction and – Rob’s specialty – commissioning. He couldn’t have had a more capable environment on which to hang the genesis of MODS Origin.

With the Project Harmony contract awarded to JGC in 2018, construction of these chemical plants in Thailand’s Hemaraj Eastern industrial estate were slated to start 2021. This massive construction project formed the basis of a high-performance synthetic resin plant, the downstream outputs of which include the production of electrical and automotive components, medical equipment and other societal necessities.

When Rob started with MODS in 2019, his responsibilities to get MODS Origin ready for such an undertaking revolved around redeveloping specific aspects of the MODS Connect software for new projects (e.g. greenfield) and mega builds. This included redesigning the structure of the software to be able to handle large amounts of data, concurrent users, circa 50,000 tags with over 150,000 inspection and test records for Project Harmony.

Previously, the Project Harmony personnel had only ever used paper-based systems and had never been exposed to a digital handover process. So, on top of his technical undertakings, Rob was also responsible for assisting in training staff in digital completions.

MODS’s collaboration with JGC on Project Harmony served as the precursor for MODS Origin, new build project execution software. Rob worked intimately with JGC’s Project Engineer, Taku Kitahara, and went to Thailand for a couple of weeks to quality assure MODS’s field-based performance.

When JGC bought forty percent of MODS in 2020, development of MODS Origin kicked off in earnest with Rob at the helm. That’s a lot of progress for barely over a year with MODS and it speaks to Rob’s ability to foster partnerships, collaborating on technological solutions to challenges inherent in mega-builds.

Rob says:

“Remote construction management of handovers allows the client to monitor, track and report on their project milestones all in real time, whilst also giving them the assurance that their assets have been constructed and commissioned to a high standard, all in a digital format.”

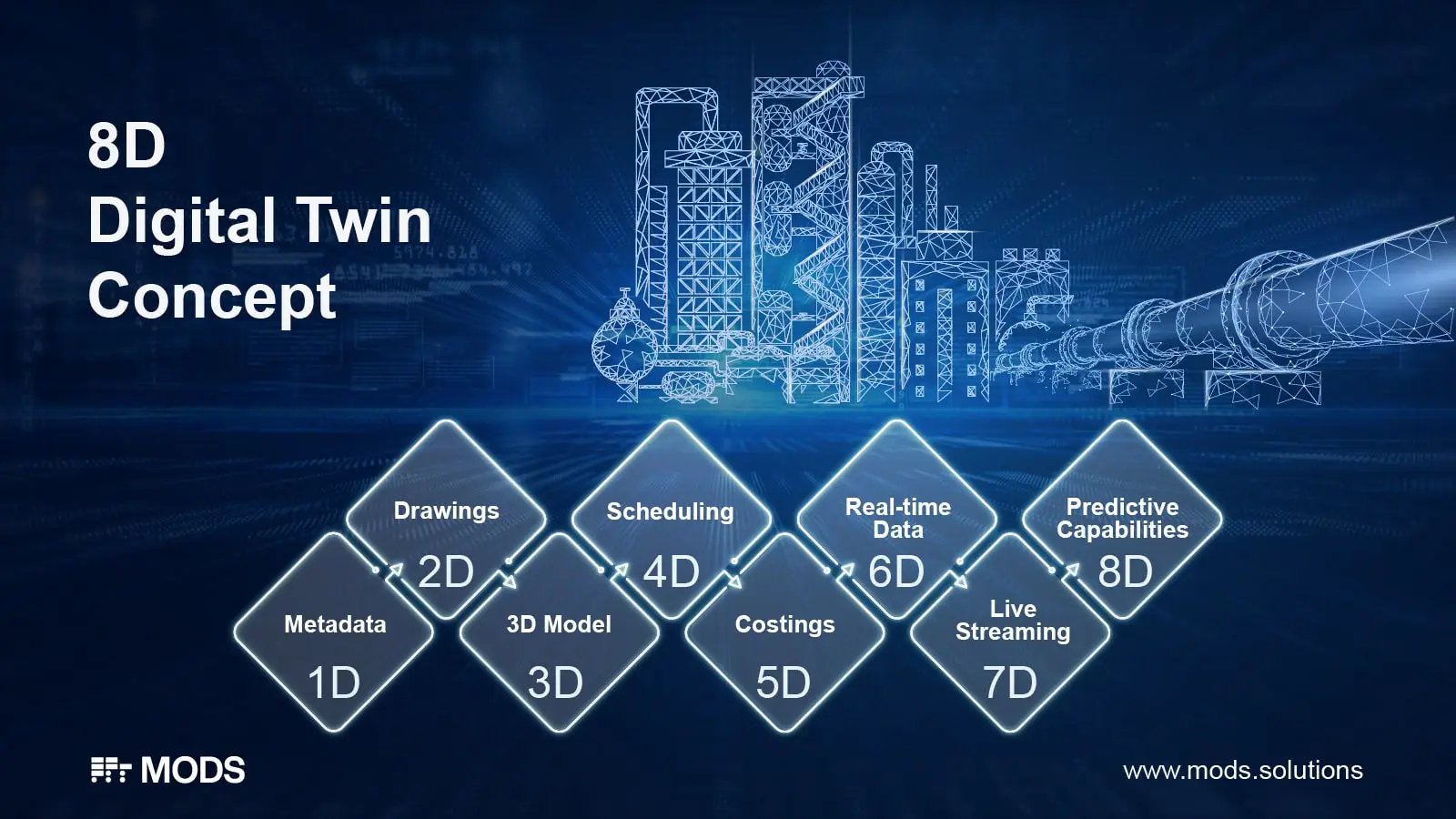

When Rob started with MODS, he describes the Reality software solution, a digital asset model used in parallel with MODS Origin, as being at the 1D-stage in the journey towards the digital twin concept (see below). The 1D phase revolves around a high-level strategy defining the operational requirements to which the virtual reality must cater.

Working closely with internal developers and with external partners, JGC, Rob is guiding this digital journey through these eight phases, and it’s been growing in leaps and bounds since.

MODS Origin is just that, the origin of an EPC digital transformation journey. Currently passing the 4D milestone with Gantt Charts and scheduling functions, Rob is delivering the joint MODS-JGC vision, bringing the next generation of MODS Origin to fruition, hedging it ever closer to the lofty 8D outcome.

Rob’s tenure with MODS predates the Origin product line, which means that he continues to be influential in its development. This ability to mold a digital product that makes the kind of site work he used to do easier, is Rob’s proudest accomplishment thus far at MODS.

He explains:

“The 8D journey is fundamentally going to change the standard of completions as we currently know it, and MODS are in the forefront of this digital journey. The Origin product was on the 1D to 2D stage back in 2019 and now we are on the path to the 4D and 5D stages. This journey not only changes the way we execute, monitor and report completions, but it also gives the client a far greater range of data/tools to allow them to make informed decisions for their current and future projects.”

With three growing girls to raise, Rob juggles work, fatherhood and motocross hobbies with an understated ease.

Transitioning from field-based projects to an office setting accommodates his three girls, though they previously spent time with their doting father in his work further afield. Laila, 16, recently finished high school with the laudable goal of becoming an astrophysicist. Scarlett, 13, is the girly-girl finishing her second year of high school, and Primrose, 6, is, well, 6.

Born and bred in Newcastle where one of MODS’s brick and mortar offices is based, Rob has enjoyed settling into the comparative luxury of having his entire family local, something he certainly wasn’t afforded in his fourteen years offshore.

The phrase “busy hands achieve more than idle tongues” is poignant in Rob’s case, who clearly keeps himself busy raising his daughters, continuing to forge an expertise in the completions of mega-projects and fostering a continued lust in his formerly competitive motocross hobby.

The lure of a stable working life on home soil with MODS was only made more appealing through his passion for all motor sports, which he shares with the Bell brothers and other colleagues at MODS. Rob’s been dirt biking since he was eight years old. He used to race and, despite taking a ten-year hiatus to accommodate his offshore career, even raced last season.

The lure of a stable working life on home soil with MODS was only made more appealing through his passion for all motor sports, which he shares with the Bell brothers and other colleagues at MODS. Rob’s been dirt biking since he was eight years old. He used to race and, despite taking a ten-year hiatus to accommodate his offshore career, even raced last season.

Passion aside, Rob won’t let his kids race because it’s too dangerous, he says. This is a fair claim. When asked what the worst accident he’s ever been in, an expressionless Rob simply holds up his right hand to reveal a missing digit, waiting for a reaction before letting out a wry chuckle. Indeed, he lost a finger in 2017 when at the Clair Ridge BP project practicing motocross. A resilient man with palpable strength of character, Rob got right back on the bike (but don’t tell his daughters).

We are sharing MODS employee stories and a lot of industry-related blogs with tips and tricks, trends, predictions, advice and a lot of useful information every week. Make sure you don't miss out on these by following us on  .

.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

A significant global contributor to economic growth and industrial development, JGC Group is an engineering, procurement and construction (EPC)...

Michael Steele started his career in 2014 as a Junior Software Developer, based out of the UK office. Together with Rich Cox, MODS Chief Digital...

Matthew Smith came to MODS in 2018 as a trainee, straight out of a Mechanical Engineering program in his hometown of Aberdeen where he grew up...