Digital Completions in Plant Modifications and Upgrades

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

3 min read

Lisa De Vellis, PE

:

Nov 5, 2021 11:45:52 AM

Lisa De Vellis, PE

:

Nov 5, 2021 11:45:52 AM

We all have them. Our children obsess over them. From video-calling to home-schooling to game-playing, the ubiquitous tablet has introduced an enormous amount of flexibility, ease and enjoyment into our lives.

Industrial-grade tablets, however, are not your kids’ devices. Superheroes of the tablet world, they enable paperless technologies because they are built to withstand harsh conditions, passing even the highest military standards.

Energy sector companies – to remain competitive – must power into the future through digitalization, cutting paper out of the process.

To succeed, digital technology needs to be accessible in a range of environments – from onshore plants to offshore construction and beyond. Only then will the benefits of reducing costs and carbon emissions, as well as enhancing safety through be fully realized.

While software solutions are the brains driving digitalization in industrial sectors, hardware solutions – like handheld devices – are the bodies that enable these paper-saving technologies. Industrial tablets are the hardware solution enabling effective digital transformation in the energy sector.

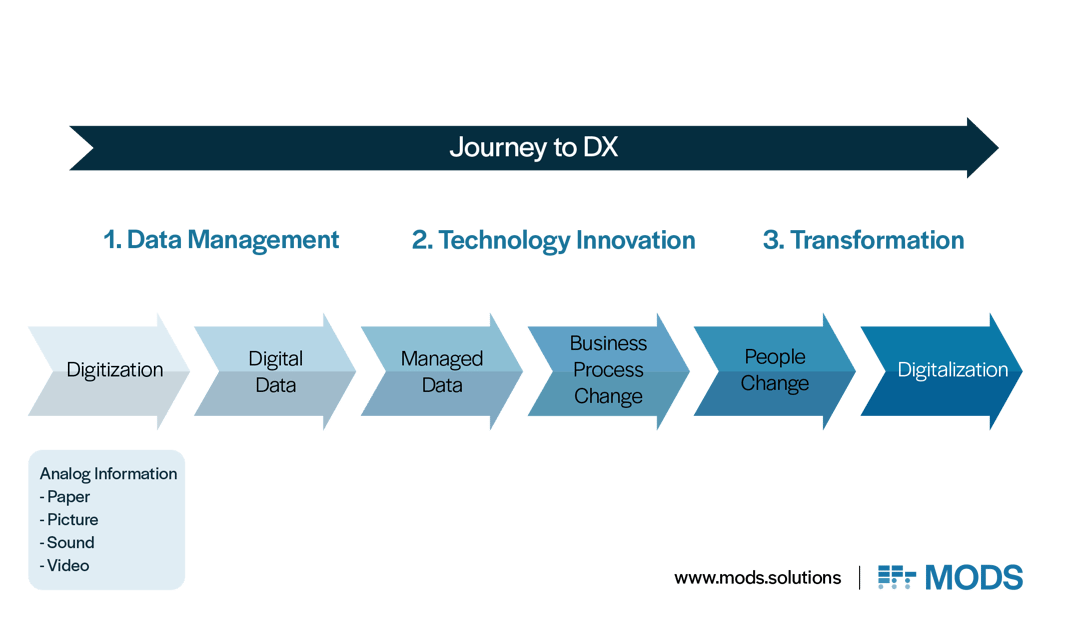

Digitalization, or digital transformation, is the adoption of digital technology that, in simple terms, replaces paper-based systems and processes with digital ones.

Digital transformation promises industrial users a plethora of time, cost and safety benefits. But unless the nuts and bolts of this transformation – digital software solutions – make it into the hands of onsite and remote workers, then paper-based processes will continue to dominate.

It is through mobile hardware solutions, like industrial tablets, that both the operational and paperless benefits of digital transformation will be harnessed.

Oil and gas is lagging with regard to industrial digital maturity. One barrier to adopting digitalization in the energy sector is the worry that handheld devices could ignite combustible or flammable materials onsite. When a device is not fit for purpose, this is a legitimate concern.

For tablets to deliver a myriad of digital solutions to onsite workers, and to keep them safe in industrial settings, the device itself must be safe. Advances in industrial tablets ensure that these devices are indeed compliant, meeting operational and regulatory specifications in the oil and gas industry. Being both flame and explosion-proof top the list in many industrial contexts.

Accrediting bodies ATEX (accepted in the European Union) and IECEx (accepted globally) certify equipment, including handhelds, for use in hazardous environments. As of January 2022, UKCA product certification will replace ATEX in the UK.

In the United States, compliance with MIL-STD-810G may also apply to industrial-use tablets. Devices specified with this US-military standard have demonstrated the ability to withstand twenty-nine shock-related tests, from temperature to gunfire.

Certainly, tablets with explosion-proof specs warrant a higher price tag than those built for consumer use. However, when considered over a five-year period, the cost of ownership of industrial tablets is actually fifty percent less than consumer devices owing to reduced device fail rates, downtime and maintenance.

The industrial tablet market is wide-ranging and suitable for a host of complex environments. Once safety-compliance is assured, it’s their user-friendly features that allow onsite workers to end their reliance on paper, minimizing both human error and waste.

Enabling data-driven mobile solutions, industrial tablets bring digitalization to both onsite workers and remote managers – alleviating their stress, not adding to it.

These hardware solutions connect people to a shared source of information. Portable and rugged, industrial tablets are now as easy for onsite workers as for their office counterparts, streamlining communications and rendering paper processes obsolete.

Fortunately, good things really do come in small packages. Portability is an obvious feature, particularly for multiple users moving around in industrial settings who may need to share the same device.

Provided the tablets are compliant and fit for purpose, they even protect energy-sector workers from the top onsite fatality hazards by introducing things like remote visualizations and remote asset inspections. Tablets also facilitate walkthroughs or other onsite validation checks.

Device portability enables software features advantageous to onsite workers, including those used in materials management like barcode scanning and radio-frequency identification (RFID) scanning.

Screen displays are designed to be easily read even under direct sunlight and can even be used by workers wearing gloves. These are not precious devices – workers don’t need to fret about dropping or getting foreign substances on them.

Purpose-built to meet all required safety standards, the ruggedness rating (semi-rugged, fully-rugged, ultra-rugged) is dictated by technical specifications that include:

Industrial-grade tablets rely on specialized software solutions to inject innovation into and optimize efficiency of operations, while saving paper.

Whether it’s 3D visualizations of offshore oil rig operations or onshore construction management requiring seamless cooperation between onsite and offsite workers, industrial tablets deliver the power of digital software solutions to the palm of your hand.

Handheld devices have rewired our brains and revolutionized our lives. Plus, handhelds enable a paperless environment, limiting both time and environmental waste. Leave the cat videos for your home tablet – it's the industrial variety that’s poised to propel the energy sector into the future.

If you are interested in implementing handheld technology into your organization, feel free to  for consultation.

for consultation.

Unlike greenfield or any new build construction projects, plant modifications and upgrades present a unique set of challenges. Work is carried out...

Turnarounds and shutdowns are among the most critical—and stressful—phases in the management and operation of industrial assets. These planned...

Offshore decommissioning and asset retirement present significant logistical, regulatory, safety, fiscal and reputational challenges. The process of...

How materials are managed in a project plays a crucial role in the project's cost, integrity, and productivity. Material-related processes, such as...

This blog is the continuation of Data-driven smart facilities and decarbonization towards a sustainable energy future.

“The more you build, the more you’re going to learn.” Lee Anthony Bordelon Sr certainly knows. He’s been with GIS – a strategic partner in global...